Since its establishment in 1978, INZI CONTROLS CO., LTD. has been devoted to the development and production of key automotive parts for 46 years, and has grown into a company recognized for its top-class technology and quality.

Last winter, many electric vehicles (EVs) were unable to operate due to the cold wave in the northern parts of North America. This is because batteries have difficulty operating in cold weather. The battery warm-up heater for EVs was thus developed to solve this problem and increase battery efficiency in winter.

Helping to extend the driving range of EVs

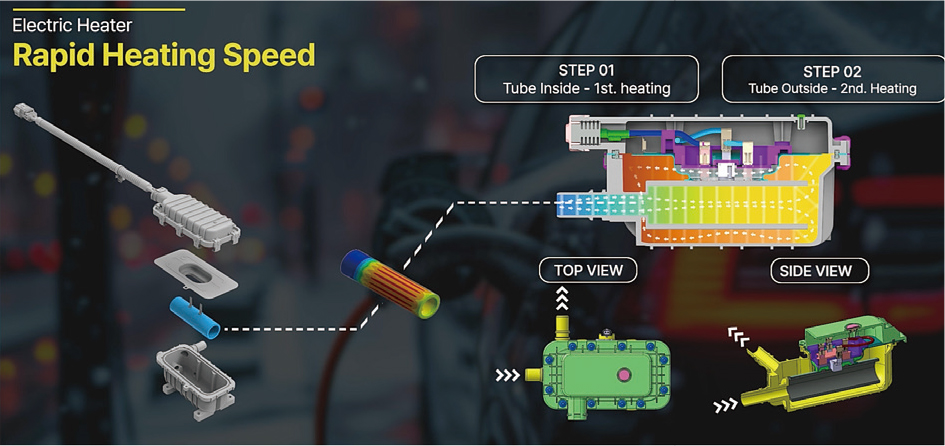

While warm-up heaters have been used before, INZI CONTROLS’ warm-up heater uses a cylindrical ceramic heating element to increase the warm-up speed. This shortens the cold start time and increases battery efficiency, thereby helping to extend the driving range of electric vehicles.

The cylindrical structure of the ceramic heating element firstly allows the fluid to heat up as it passes through the heating element, and then secondly to heat up as it passes through the outside of the heating element – thereby maximizing the heat transfer between the heating element and the fluid, resulting in rapid warm-up and high thermal efficiency.

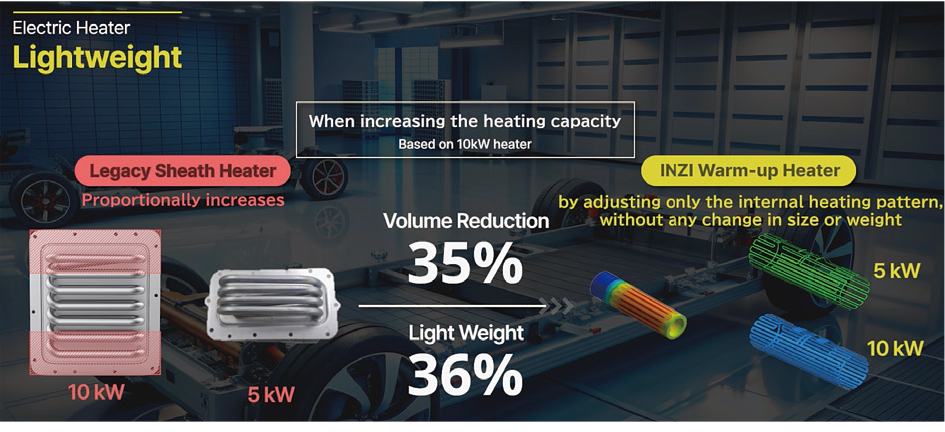

Assuming that the target temperature of the battery pack is 21˚C, based on the 10kW capacity of the warm-up heater, INZICONTROLS’ warm-up heater delivers a warm-up speed that is 58% superior to the existing sheath heater.

Also, when the capacity of the warm-up heater increases, the size of the heating element generally increases proportionally. However, the ceramic heater of INZI CONTROLS can respond to various capacities with the same volume by controlling the internal heating pattern. Moreover, INZI CONTROLS’ warm-up heater is 35% smaller in volume and 36% lighter in weight than the existing sheath heater.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

Leave a comment