Hyundai Minuteness Co., Ltd. has maintained a strong presence in the construction heavy equipment parts industry since its founding on April 1st, 1979.

In December 2005, Hyundai Minuteness expanded its operations by establishing a subsidiary in Shanghai, China, and has since relocated its primary production facilities to Linyi, Shandong Province.

Hyundai Minuteness’ expertise lies in manufacturing high-quality shock absorbers for excavators and steering wheels for forklifts, backed by reliable technology. On a global level, Hyundai Minuteness is supplying excavator components to Volvo Excavator Plants and steering wheels to Clark Forklift Plants.

Recoil Spring Assembly

This component is part of the lower frame of excavators and is designed to be assembled with the Idler Assembly. It maintains consistent tension in the caterpillar tracks, allowing for smooth rotation. Additionally, it functions as a shock absorption device, reducing the impact on the Idler Assembly during collisions with obstacles.

In particular, when colliding with rocks or other obstacles, it mitigates the direct impact transferred to the idler, thereby extending the lifespan of key components and reducing maintenance costs.

Idler Assembly

This component is essential for the lower frame of excavators and caterpillar tracks. The Idler Assembly serves as a guide, ensuring continuous rotation of the caterpillar tracks, while the Recoil Spring Assembly absorbs and buffers impacts, thus protecting the tracks from damage.

It guides the track to prevent derailment within the track system and maintains consistent movement during both forward and reverse operations, thereby delivering excellent durability and performance even in rough working environments.

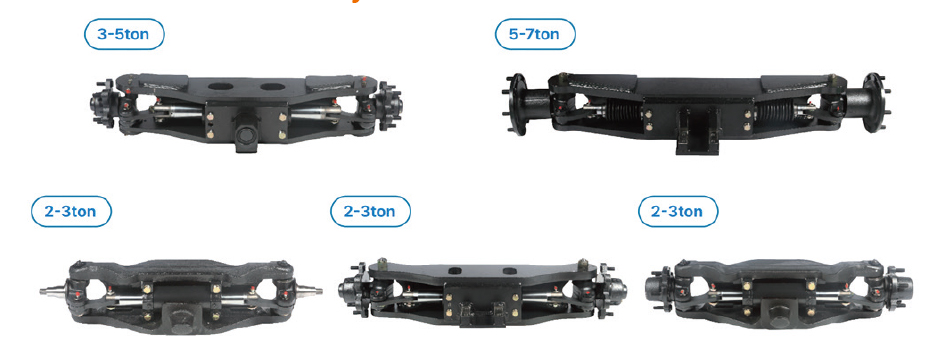

Steer Axle Assembly

This component is mounted on the rear of the forklift’s lower frame and changes the vehicle’s direction in response to the driver’s steering input. It is designed to enable agile and stable steering even within a small turning radius.

“In our commitment to global market expansion, we are continuously improving our processes by upgrading our smart factory with advanced 3D design, optimized manufacturing processes, and maximum productivity. We have also implemented an intelligent quality-management system and established an ESG-management framework. We are committed to delivering the best products and services to all our customers,” the company’s CEO remarked.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

Leave a comment