[INQ. NO. 2512M04] NEGENTEC CO., LTD. is a manufacturer of plastic reinforced healds using new production technology with high-solid compound plastic.

Plastic healds could not be combined with healds by catapulting under a thickness of 0.6m/m when trying the existing catapulting method. However, through one and a half years of hard work by NEGENTEC’s developers, they achieved catapulting under a thickness of 0.4m/m by a new production method, and as a result, NEGENTEC has succeeded in the manufacturing of plastic healds for the first time in the world and has come to manufacture the brand, HIPER HEALD.

As a specialized company focusing on research and production of plastic healds since its founding in June 2001. By developing healds, which had previously been highly dependent on imports, through accumulated technologies along with endless research and development, NEGENTEC is now advancing as the leading company of the heald-production industry in the 21st century with its world-leading technology.

NEGENTEC is manufacturing and supplying industrial plastic healds, etc., used in P.P looms, and air bag weave.

The superiority of NEGENTEC‘s plastic healds are also gaining recognition in foreign markets including Japan and China. Of special note in August 2006, an international textile machinery maker, STAUBLI, visited NEGENTEC in person and adopted its NEGENTEC product from among automatic plastic healds for weavers.

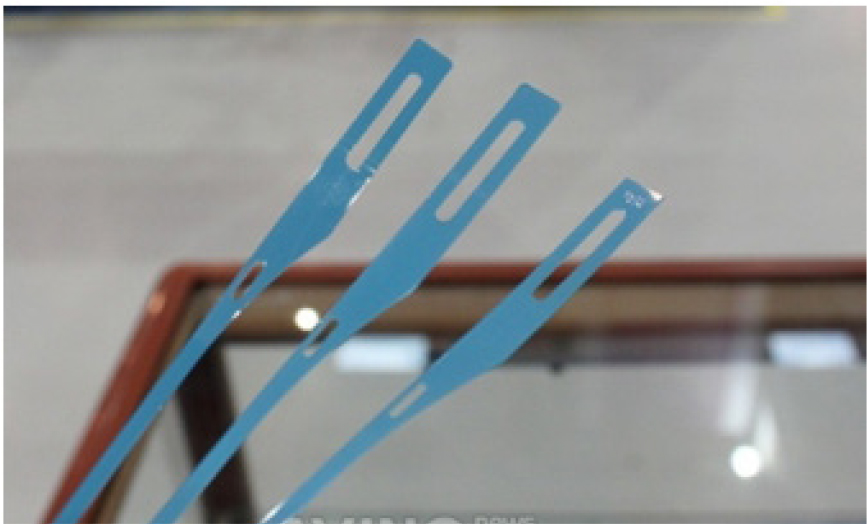

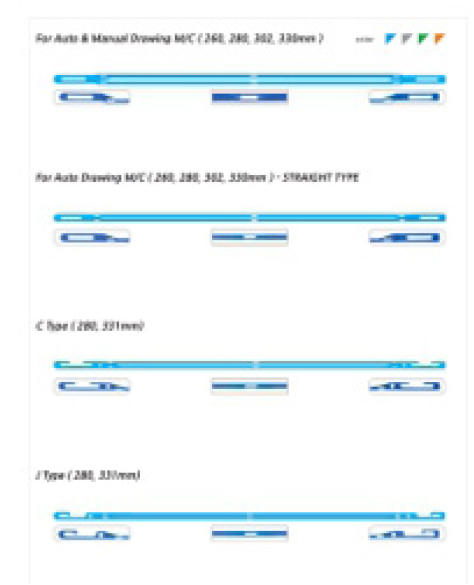

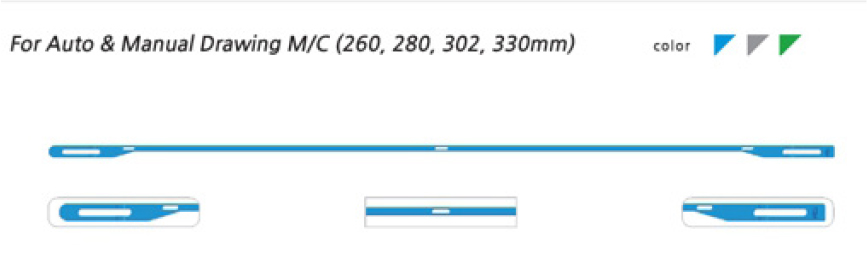

Hiper Heald

NEGENTEC’s hiper heald has excellent durability with differentiated materials. It maintains the world’s best quality with long experience and strict quality control. The company produces hiper heald with various specs and colors. Customers can choose from these different types to suit their particular needs, so they basically feature higher usability for high density.

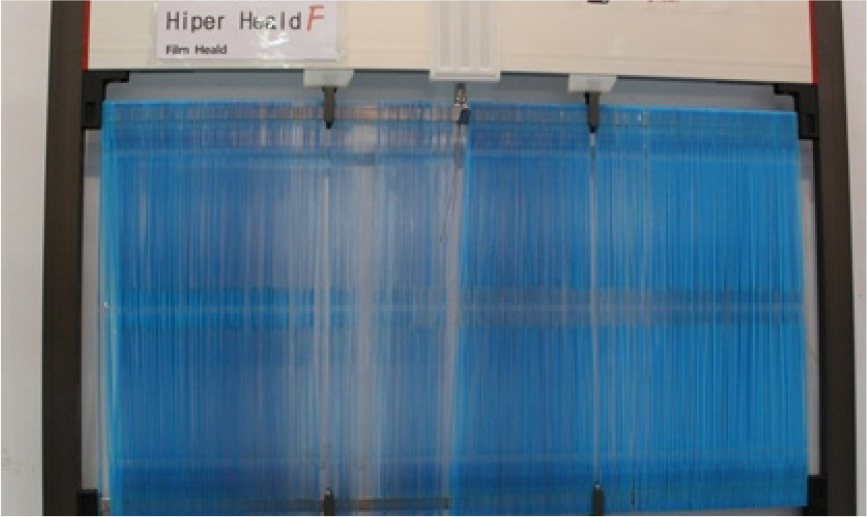

Hiper Heald (Film Heald)

Negentec developed film heald through its new process. In particular, after improving a section that used to be a problem with the existing method, the company can now offer a much better product.

Also, Negentec reduced problems with the slope caused by heald while weaving, thereby improving weavability and minimizing the rate of inferiority. The product thus improved problems of existing film with this self-developed process. Diversification of applied weaves with various kinds of films and colors is possible. As the thickness of existing plastic was improved, it is useful for high density weaving.

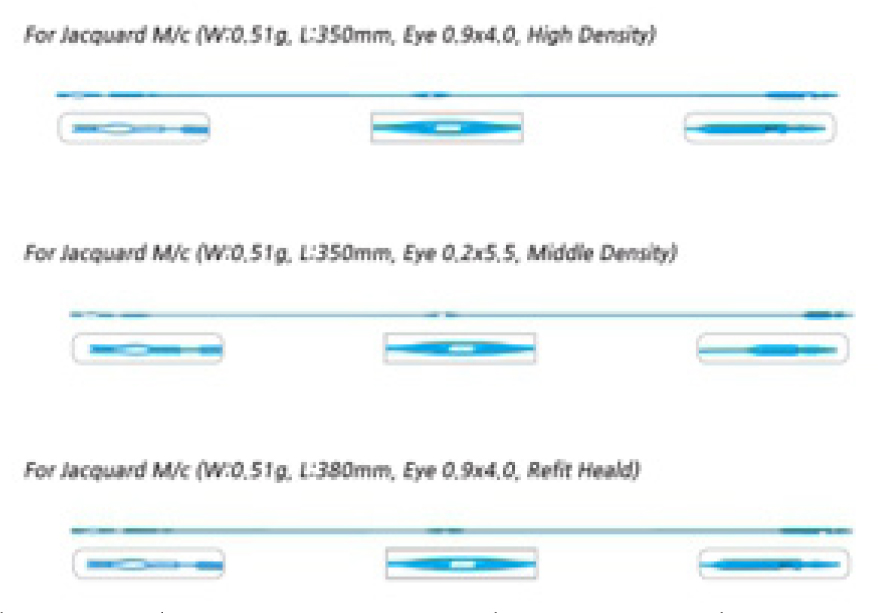

Jacquard Heald

Based on its cutting-edge plastic-production technology, NEGENTEC has developed and supplied the world’s first plastic heald for electronic cards.

NEGENTEC offers a diverse range of products, including high-density and general-purpose products, expanding the range of choices for weaving companies and enhancing their competitiveness. It also produces spring sets for electronic jacquard, including high-quality springs and related components.

NEGENTEC is currently supplying its products to an enterprise using the automatic weaver of STAUBLI. NEGENTEC has acquired a patent on its utility model in Korea, plus international patents in Japan and China.

“We are committed to continuous improvement in technologies and strive to become a company that can meet the expectations of the textile industry through researching and developing new products in the future,” commented the company’s CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

Leave a comment