Softmill Proves its Competitiveness in Global Markets

Winning the $2 Million Export Tower at the 62nd Trade Day

[INQ. NO. 2601M08] On the occasion of the 62nd Trade Day, Softmill won the $2 Million Export Tower in recognition of its outstanding export performance and growing competitiveness in the global market.

This achievement represents a meaningful milestone, made possible by the company’s continuous investment in technological innovation, strict quality management, and customer-oriented business philosophy.

Through close cooperation with overseas partners and a consistent commitment to meeting international standards, Softmill has successfully expanded its global footprint and strengthened long-term relationships across multiple markets.

Building on this recognition, Softmill remains dedicated to delivering reliable products, advanced solutions, and sustainable value to customers worldwide, while continuing its steady growth as a trusted global business partner.

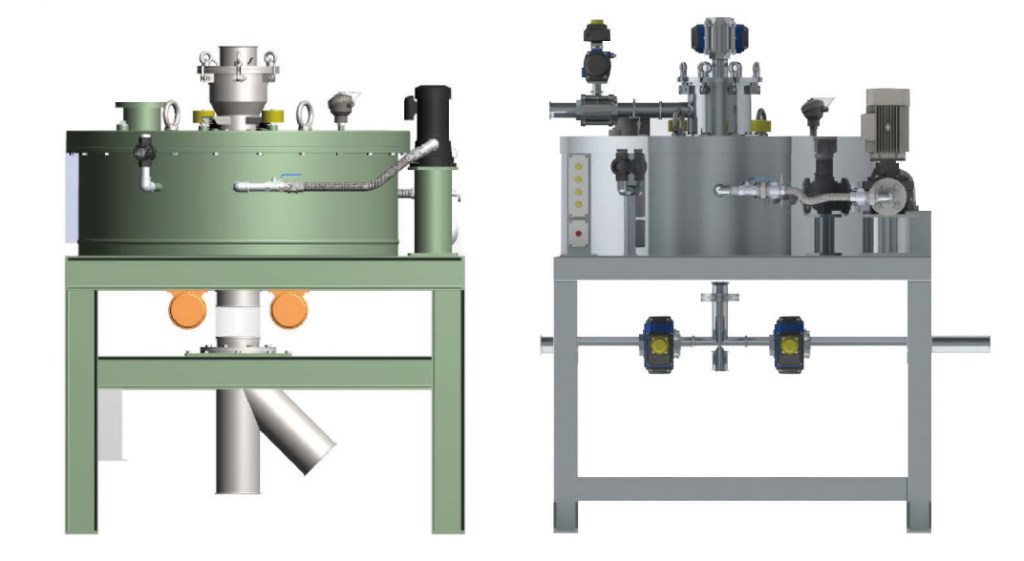

Hybrid Dough Conditioner

Outstanding Overseas Store Case: Childish Bakery, Texas, USA

At Childish Bakery in Texas, USA, an outstanding overseas store, the hybrid dough conditioner has proven its performance in a high-volume production environment.

Featuring an eco-friendly heat exchange natural humidification system, the unit generates moisture independently without the need for additional humidification devices, maintaining a precisely controlled high-humidity environment.

By minimizing moisture loss, the system allows dough to be stored for up to 40 hours without drying, supporting long fermentation processes and stable production throughout extended operating hours.

This reliable dough management solution enables consistent quality and high productivity, contributing to strong customer response, particularly for popular items such as salt bread.

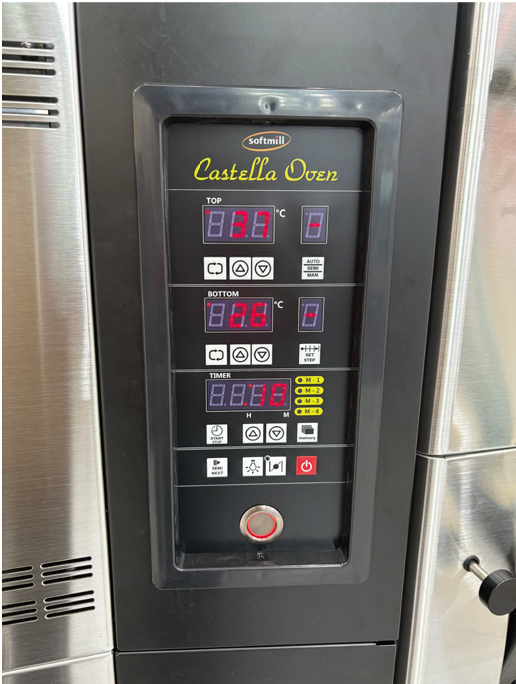

Deck Oven & Softmill Proofer

Outstanding Domestic Store Case: Ihwa-dong Bakery, Korea

As an outstanding domestic bakery in Korea, Ihwa-dong Bakery operates deck ovens in combination with the Softmill Proofer to maintain stable and consistent production.

The deck ovens feature a heating system that delivers uniform temperature distribution throughout the baking chamber, along with excellent heat retention, ensuring even coloration and reliable baking results across all products.

Supporting the fermentation process, the Softmill proofer is equipped with a nozzle spray humidification system that maintains sufficient humidity in a clean and hygienic manner. Its uniform airflow design evenly distributes temperature and humidity inside the chamber, minimizing differences between upper and lower trays.

This balanced baking and fermentation environment plays a key role in preserving the consistent quality of the bakery’s signature olive bread, and contributes to high customer satisfaction.

These domestic and international best practice cases demonstrate how specialized baking and fermentation solutions support bakeries worldwide by delivering consistent product quality, improved operational efficiency, and sustainable long-term value.

Introducing the Company and Product Portfolio on YouTube

“To further introduce our company and product portfolio, we have uploaded company and product introduction videos on YouTube. The videos are available in English (U.S.), Japanese, Chinese, Arabic, and Vietnamese and can be accessed by scanning the QR code shown at the bottom right of this page,” a spokesperson for the company stated.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods