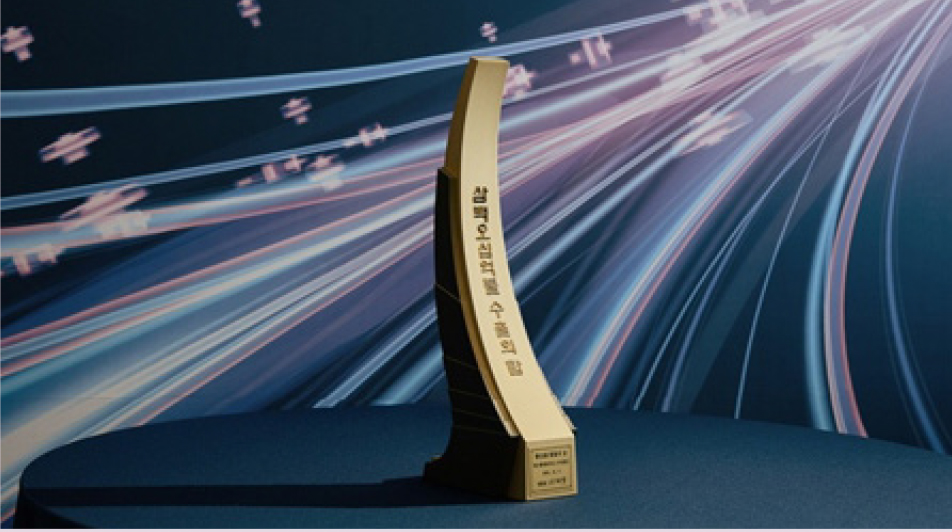

Winning the $300 Million Export Tower

[INQ. NO. 2601M07] Hyundai Steel Pipe, a global steel pipe specialist, received the $300 Million Export Tower at the 62nd Trade Day ceremony.

Hyundai Steel Pipe, with an annual production capacity of 660,000 tons, achieved cumulative export volume of $350 million, following exports of $220 million in 2024 and $130 million in the first half of 2025.

Based on six world-class products, including Oil Country Tubular Goods (OCTG), Hyundai Steel Pipe is recognized for successfully securing global technological competitiveness and steadily expanding its customer base.

North America, which accounts for 95% of total exports (USA 91%, Canada 4%), is considered a key market for the company. Furthermore, Hyundai Steel Pipe has been actively exploring new markets such as the Middle East, Australia, and Central & South America, achieving exports of $6 million to Saudi Arabia and $1 million to Australia and Colombia, respectively, in the first half of last year alone.

In particular, Hyundai Steel Pipe has attracted significant attention by entering the Canadian OCTG market through the reactivation of idle heat treatment facilities within its plant. Going forward, the company plans to expand its sales network and continuously expand exports by collaborating with local distributors. With cumulative exports currently reaching $10 million, the company saw a very notable increase in exports to Canada, thanks to its signing of Memorandums of Understanding (MOUs) with two additional companies.

Furthermore, the company is expanding its business in the Middle East, successfully supplying HIC (hydrogen-induced cracking) steels, a highly technical material, to Saudi Aramco, the state-owned oil company.

Following the $5 million contract for the Amiral project in 2024, Hyundai Steel Pipe secured a stable order base last year with a new $11 million contract. Furthermore, investments in heat-treatment facilities in heavy caliber of LSAW steel pipe plant have improved residual stress removal capability by 120%, thereby strengthening high-quality production capabilities.

Hyundai Steel Pipe’s technological development and research activities are also noteworthy. First, the company developed multi-PSA technology based on multi-stage heat treatment, enhancing low-temperature toughness. Furthermore, the company’s introduction of an automatic welding-heat input-control system has improved the defect rate by 30%. Furthermore, its installation of a three-pole internal welding machine on the spiral line has enhanced productivity (up 5%) and reliability.

For research and development, Hyundai Steel Pipe is currently working on the Ministry of Trade, Industry and Energy’s technology development of steel pipe for 485MPa-class high-pressure hydrogen pipe — with an annual budget of KRW 1.5 billion — by utilizing its research institute. Furthermore, the company has achieved international performance certification from RINA through the development of water-resistant deodorization materials, tube mill technology for hydrogen pipe, and evaluation methods. These efforts are expected to contribute to the expansion of the hydrogen infrastructure industry.

Furthermore, Hyundai Steel Pipe is strengthening its ESG system to achieve carbon neutrality and sustainable management. Its Ulsan plant’s carbon emissions are being restricted to 62% of the previous year’s level, and it is working to reduce energy costs by over KRW 700 million annually through acquisition of domestic environmental product declaration (EPD) certification, implementation of the power demand response (DR) system, and 14 facility improvements.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods