[INQ. NO. 2512M12] Yuk-il Agrow Spun Curtain Co., founded in 1991, is a manufacturing and distributing company specialized in heat-conservation material such as house-heating curtains and screens. It is continuously researching and working to help to increase the incomes of farmers and reduce heating energy costs, which is the most important factor in this era of high oil prices.

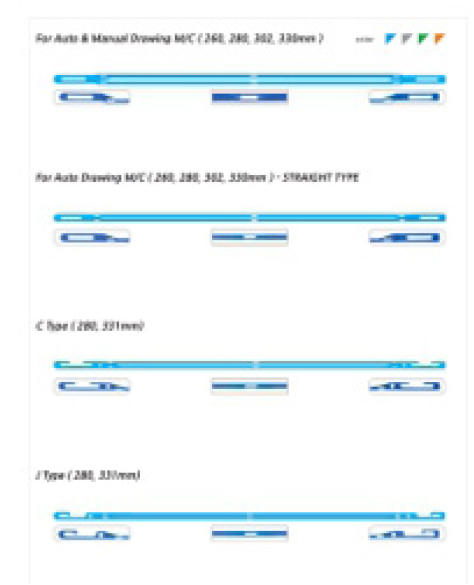

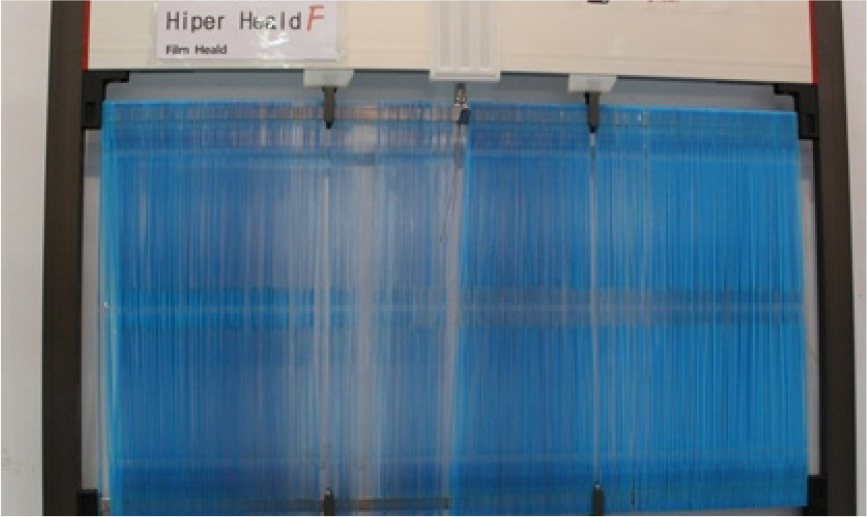

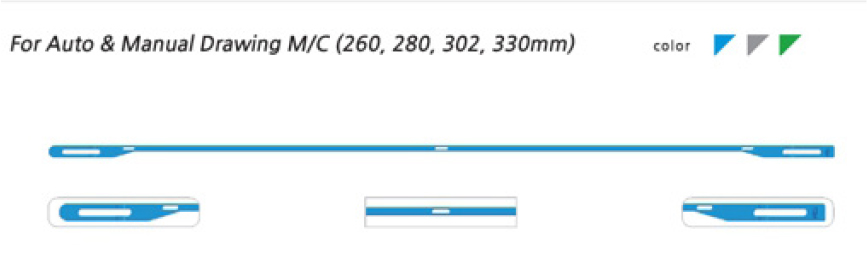

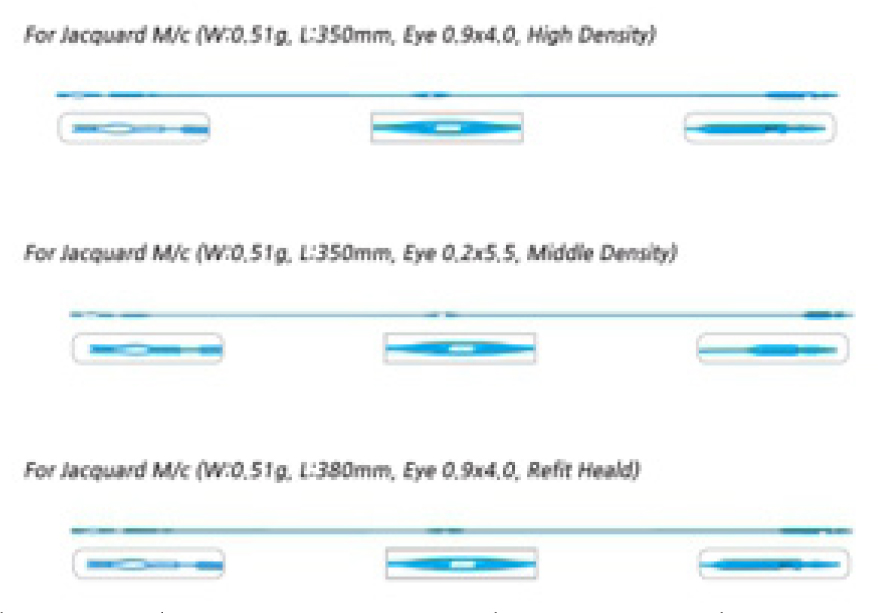

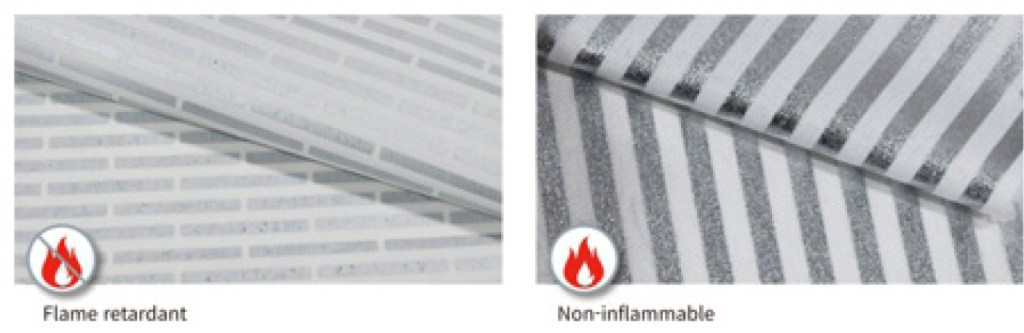

Yuk-il’s aluminum shading screen YI-AL has excellent thermal effect compared with other screens.

It is a screen product made of fabric, so there is no stretch at all. It successfully completed tests for thermal insulation, light blocking, and UV life at domestic and Japanese testing institutions. The inside of the buildings is brighter, since the aluminum powder reflects ultraviolet rays.

It has a long lifespan, excellent heat retention, and excellent dehumidification properties. Additionally, it reflects excessive sunlight in summer to regulate light intensity, and in winter, it maintains greenhouse temperature by reflecting radiant heat, thereby assisting crop growth.

Th company’s agricultural aluminum shading screens are widely used in smart farms, which are currently being built and implemented in many areas, and are also widely sold to general farmers. These products help maintain the optimal environment for crops by controlling the amount of light inside.

Recently, greenhouse cultivating sites require the production of high-quality and high-income garden crops by using additional facilities more efficiently. Accordingly, the smart farm industry is mainly propelling development of various additional facilities, cultivating management skills, energy saving and automation and is actively participating in reducing carbon dioxide, which is an issue around the world.

“We take the lead in not only cultivating high-income crops and saving energy but also automating various greenhouse cultivations. We will grow to become the people’s corporation that prioritizes the expansion of domestic and overseas markets through the development of new products and customer satisfaction,” explained the company’s CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods