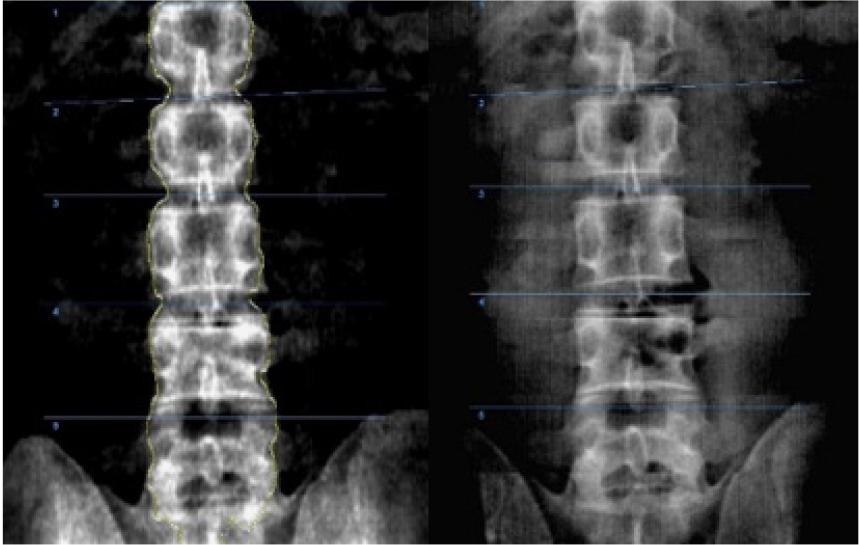

[INQ. NO. 2510M11] InAlyzer AIR, which utilizes 4-channel true fan beam technology, is the only fan beam DXA bone-density measuring device in Korea that provides raw image mode.

InAlyzer AIR provides both raw images and BMD images, allowing high-resolution bone images to be viewed, along with measurement results, through PACS. It provides a fast scanning speed of 30 seconds, and high-resolution images.

And the high-resolution images provided through the product not only increase the convenience of setting an accurate ROI, but are also a great help in deriving accurate diagnostic results.

In addition, this bone-density measuring instrument provides various diagnostic tools through intuitive software to enable convenient and accurate measurement. By maintaining the performance of the equipment through maintenance, the user can always obtain reliable results, and by adopting an open design (design patent), it helps in measurement.

The external structure of the product is minimized (1850 x 800 mm) and the scan area is maximized (490 x 900 mm), thereby increasing space efficiency for easy installation and use, even in narrow spaces.

MEDIKORS is increasing its market share through nationwide distributors in Korea, and its market share is gradually increasing overseas as well. Currently, the company is carrying out important projects in various countries, and it is estimated that the results will soon lead to strengthening its brand image and increasing global sales.

MEDIKORS is constantly focusing on developing new products by incorporating new technologies. It completely excludes the outdated practice of following or slightly developing fixed ideas and existing technologies. It is instead accelerating the development into products of transformative technologies that only this company can do.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods