READi Robust Machine develops and provides its Hydraulic Energy Recovery System (READiX), Electric Retrofit Excavator Solution (READi EX), and IoT Monitoring Platform — aiming to achieve carbon neutrality in construction machinery.

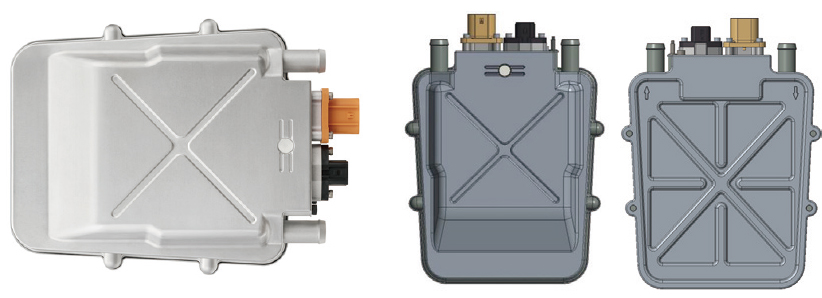

READiX

READiX is a non-invasive solution that stores hydraulic energy generated when an excavator’s boom is lowered, in an accumulator, and recycles it. This allows for a direct recovery and reuse of hydraulic energy, rather than converting it into electricity using batteries. This cuts fuel costs by an average of 20% to 30% and features a retrofit design that does not impact the structure or warranty of existing equipment.

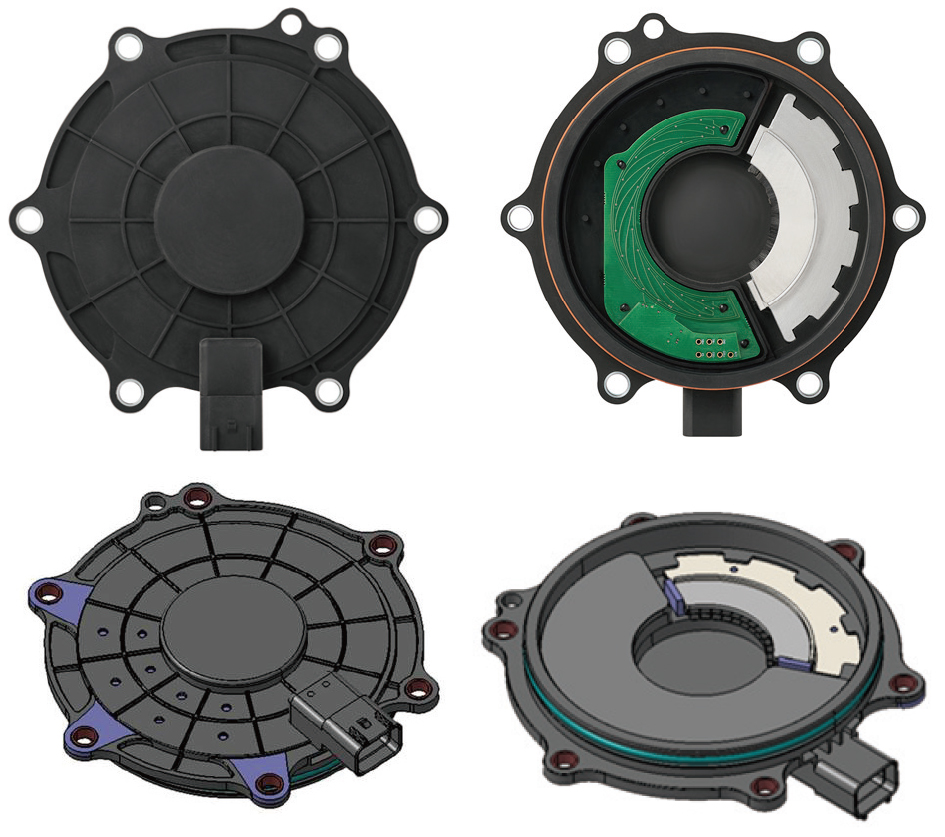

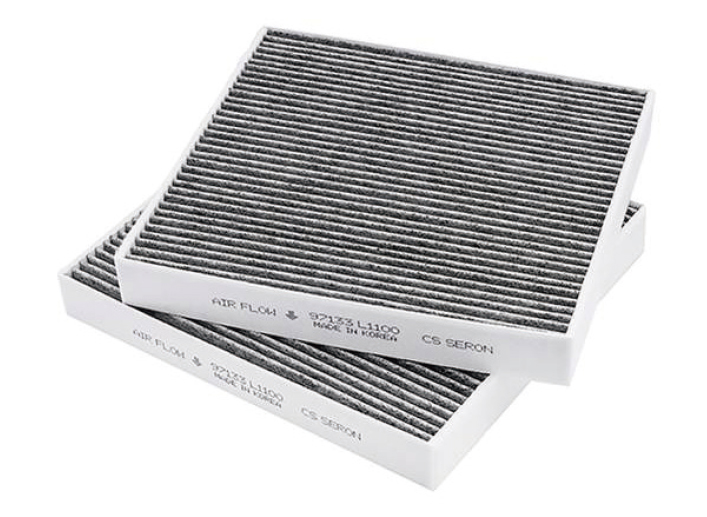

READi EX

READi EX is technology that converts diesel excavators into wired electric excavators, simultaneously reducing fuel costs and carbon emissions in stationary work sites.

By replacing an engine with a three-phase electric motor, it enables immediate zero-emission operation. Since it does not use diesel fuel, it can be converted to an eco-friendly machine without the need for a DPF or SCR device. This eliminates the need for urea water and refueling, enabling continuous operation for extended periods of time, and thereby boosting work efficiency.

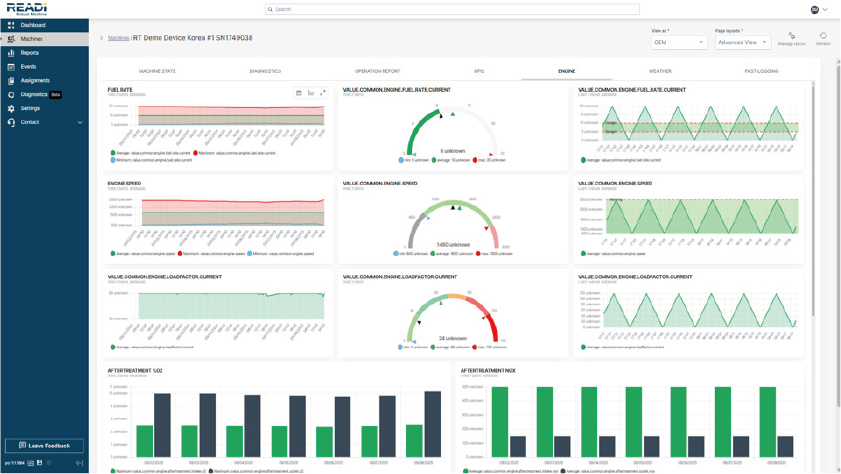

READi IoT

Furthermore, READi IoT provides operational data analytics including operating hours, idling and fuel usage, to optimize equipment operation efficiency and maintenance cycles.

The three solutions are interlocked to provide integrated support for higher energy efficiency, carbon reduction, and operational data management. They are drawing much attention as GX (Green Transition) technologies in global markets including Japan and Korea.

READi Robust Machine develops innovative technologies for improving energy efficiency and the electrification of construction equipment, and efficient equipment management by construction equipment operators. Through its Hydraulic Energy Recovery System (READiX), Electric Wired Excavator Solution (READi EX), and IoT Operation Monitoring System, the company simultaneously boosts the fuel efficiency of equipment, cuts carbon emissions and streamlines operation management.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods