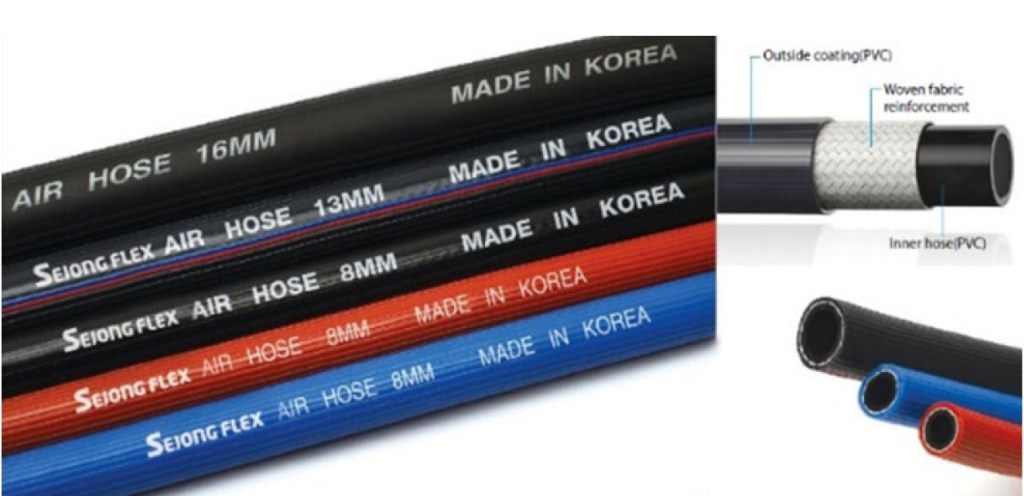

[INQ. NO. 2509M17] Sejong Flex has grown as a company having the highest level of competitiveness, and specializing in manufacturing PVC hoses on the basis of technology and experience it has accumulated over many years.

Skilled engineers produce Sejong Flex’s PVC hoses, so the quality of all its products is fully assured. Customer satisfaction is the company’s first priority. The quality PVC hoses are supplied at reasonable prices at the right time.

Platinum spray hoses

Sejong Flex’s platinum spray hoses are designed to deliver high-pressure resistance, excellent elasticity and flexibility, outstanding wear resistance, and strong durability.

The great tensile force from special woven fabric ensures its outstanding performance in durability. These hoses are used in various agricultural fields including pest control, transferring compressed water and air.

Platinum air hoses

Sejong Flex’s platinum air hoses are products intended to provide high-pressure resistance, excellent elasticity and flexibility, outstanding wear resistance, and strong durability.

The great tensile force from the special woven fabric ensures its outstanding performance in durability. Transferring high-pressure air and water, these hoses are applicable to in-plant and outdoor applications, high-pressure air supply lines, and pneumatic tools.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods