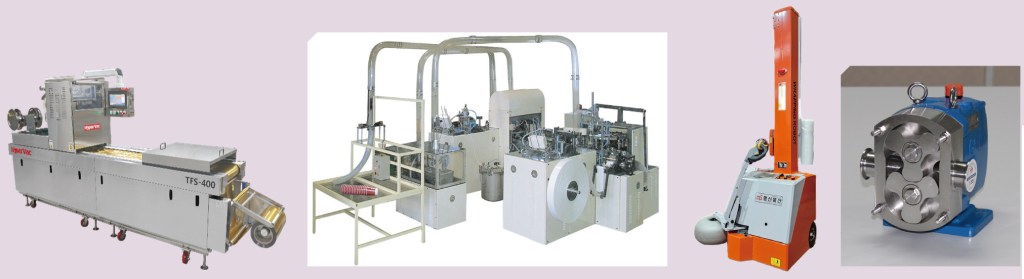

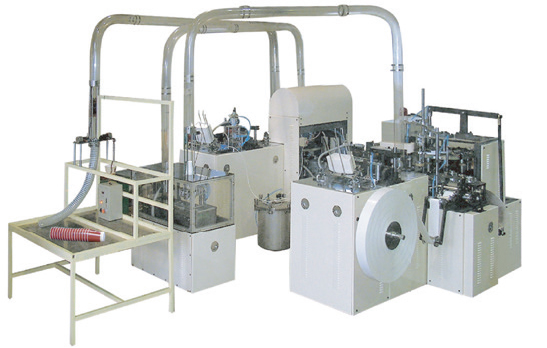

[INQ. NO. 2410M64] FUTURE PACK CO., LTD. is one of the leading manufacturers & exporters in the field of paper cup converting machinery in Korea.

FUTURE PACK started as a manufacturer of paper cup machines, handle cup machines, paper cup sleeve (two-layer coffee, noodle & plastic cup) machines, blank punching (die cutter) machines, printing & punching machines, blank offset printing machines, paper plate (tray) machines, take away box (food pail box) machines, aluminum foil food container forming machines, and other packing-related converting machinery.

FUTURE PACK’s sub-factory has been exporting around 1,000 sets of equipment to worldwide customers since 1985, and has thus risen to be at the head of this industry in Korea.

FUTURE PACK’s export countries are: The Americas (USA, Canada, Mexico, Honduras, Venezuela, Chile, Peru, Ecuador, Colombia, Brazil, Argentina, Bolivia); Europe (UK, France, Netherlands, Germany, Italy, Russia, Ukraine, Belarus, Poland, Bulgaria, Romania, Greece, Turkey, Cyprus); Middle East (Palestine, Israel, Jordan, Lebanon, Saudi Arabia, Iran, Iraq, Kuwait, Qatar, UAE, Oman); Africa (Nigeria, Kenya, Sudan, Egypt, Algeria, Libya, Tunisia); Asia (India, Pakistan, Thailand, Vietnam, the Philippines, Malaysia, Singapore, Indonesia, Australia).

FUTURE PACK’s accumulated technologies and experience guarantee the highest quality products at very competitive prices.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods