[INQ. NO. 2407M18] KORINA Co., Ltd., as a leading supplier of stainless-steel sinks, has contributed to creating the best kitchen lifestyles by producing excellent kitchen appliances with the latest facilities and cutting-edge technology.

The recent kitchen lifestyle trend focuses on making the kitchen a unique companion for people in their daily lives by creating the most useful and appropriate kitchen appliances.

In line with this trend, KORINA strives to create an ideal kitchen culture that is ahead of the times, based on its craftsmanship and cutting-edge technology.

KORINA is constantly researching new products for the kitchen appliances development business — and it is working hard on development to present more luxurious and advanced unique designs, with quality that does not lag behind, and at competitive prices.

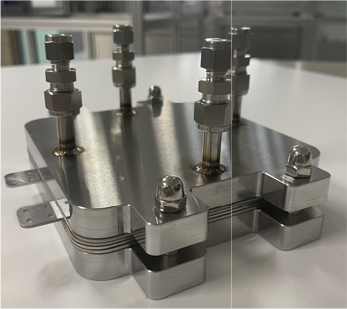

Sinks made with high-grade stainless-steel material

KORINA’s sinks are manufactured using high-grade stainless-steel material complying with the internationally recognized grade 304 (18-8 Chrome/Nickel), and the thickness varies according to the structural strength provided by the actual sink insert design.

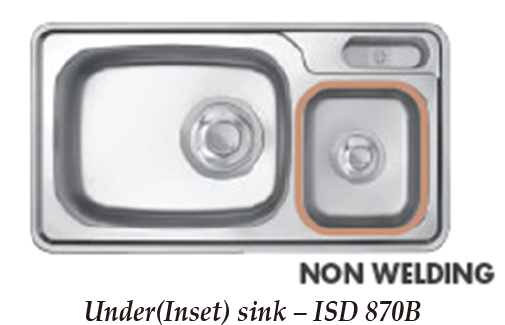

KORINA offers a variety of stainless-steel sinks with excellent functional durability and appearance. With a combination of various sink balls, ranging from one to three sink balls, its customers’ choices have been further expanded.

KORINA is a sink manufacturing company established about 21 years ago, and is producing products based on solid quality and technology.

Supplying various types of sinks to suit each country’s market

KORINA is actively exporting its products to more than 20 countries. It can provide various types of sinks to suit each country’s market, including under sinks, inset sinks, and layon sinks, as well as recently, square ball sinks. In addition, sinks are mainly made of the highest-quality AISI 304, and the design and thickness can be adjusted according to customer needs.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods