[INQ. NO. 2503M08] ALUS Co., Ltd. was established in 1999, and specializes in the manufacturing and supply of aluminum alloy casting, extrusion, and aluminum automotive parts.

In particular, ALUS has established an integrated production line in-house, enabling it to maintain a competitive quality-control system and cost competitiveness.

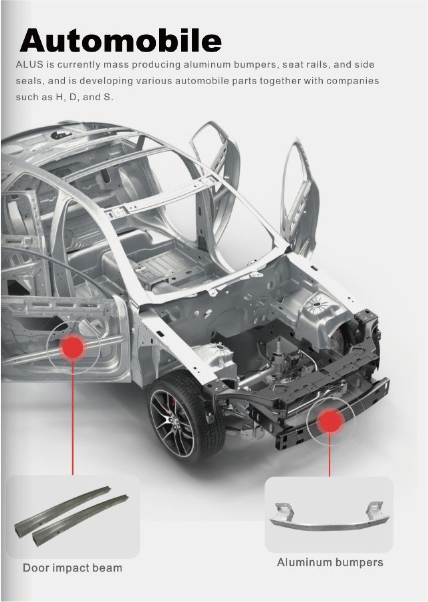

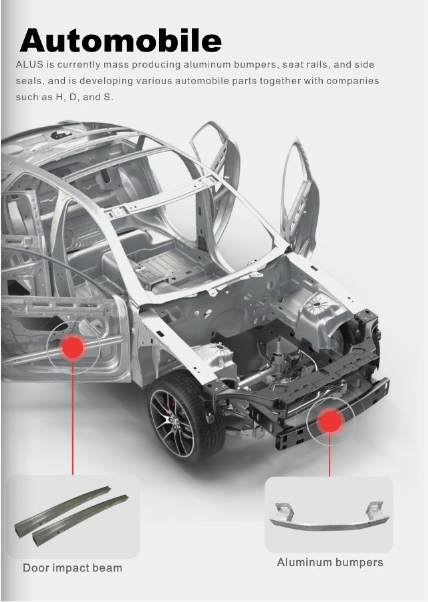

By developing lightweight materials for automobiles, ALUS mass-produces and supplies aluminum battery-pack case components, bumper beams, side sills, seat rails, etc., to Tier 1 and Tier 2 suppliers. Through these efforts, ALUS contributes to reducing carbon emissions and maximizing energy efficiency, driving its continuous growth.

Additionally, ALUS has received positive feedback from buyers in overseas markets, highlighting its potential for expanding exports to the global market in the future.

Aluminum car body parts

These parts require precision extrusion and quality control due to their large size and intricate design.

ALUS completed the construction of a 12-inch large extrusion manufacturing line (4,500 tons) in 2017 and established additional extrusion manufacturing facilities, including an 8-inch (2,200 tons) and two 7-inch lines in 2022, thus creating a production system capable of handling various sizes of components.

Furthermore, a smart factory has been established to build precise and high-quality management capabilities in mass-production processes.

Currently, automated inspection equipment utilizing robots and laser sensors has been introduced and is being applied to mass-production lines to ensure accurate inspection and management of intricate automotive parts.

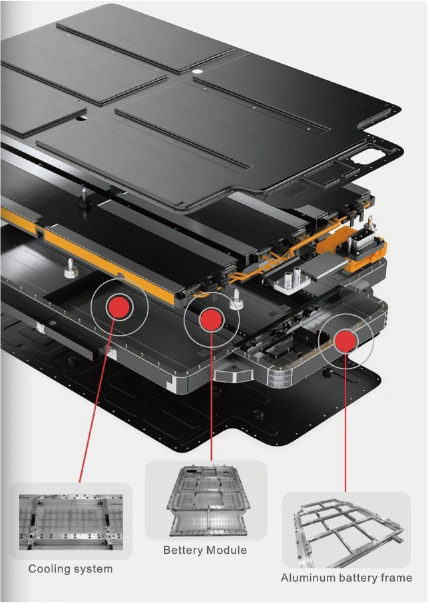

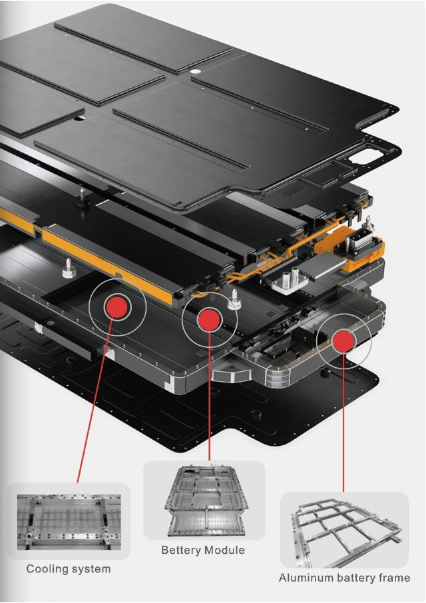

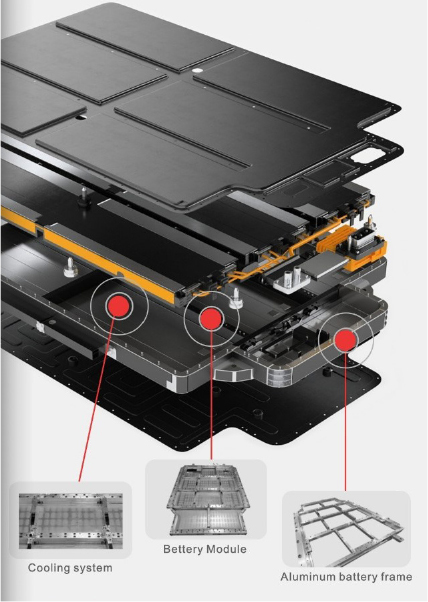

Aluminum battery pack case parts for EV

The pack case containing the battery modules is a component made by extruding aluminum material, followed by heat-treatment and machining for lightweight purposes.

It is assembled with top, bottom, left, right, and partition walls – and is designed in various shapes and sizes, according to the battery pack size, requiring stringent dimensional specifications.

As the outer component of the battery pack case, which protects the battery modules and cooling system from thermal and mechanical shocks, it requires high-strength, high-precision aluminum extrusion technology.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods