[INQ. NO. 2512M13] With 30 years of experience in the automotive industry, JWON PROTECH has established itself as a specialized company in equipment and chemicals for automotive engine performance restoration.

JWON PROTECH is committed to always providing the highest quality and performance from its customers’ perspective.

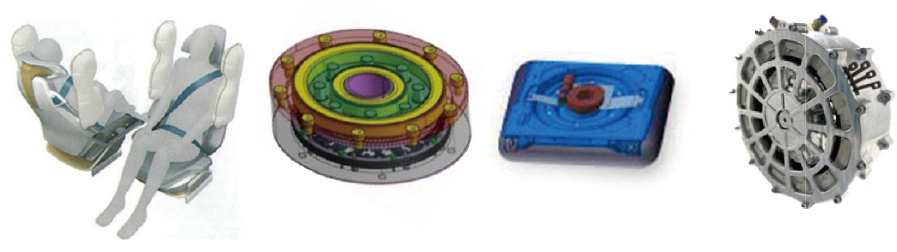

Injector-Cleaning Equipment

Petroleum-powered internal combustion engines generate carbon as they operate. This carbon accumulates in the engine combustion chamber and fuel injector ― thus interfering with fuel injection, reducing engine output, and causing engine knocking and failure.

To address these issues, it is essential to clean the fuel deposits in the control valve inside the injector, removing foreign matter, restoring valve stem clearance, and restoring performance. In addition, when a field phenomenon occurs, such processes as the performance of injector cleaning, high-quality injector-cleaning results, and restoration of static leakage values to normal levels, are all crucial.

JWON PROTECH’s chemicals dissolve carbon deposits in the fuel injector and combustion chamber without harming the engine. Periodic application helps maintains the new feel of the vehicle.

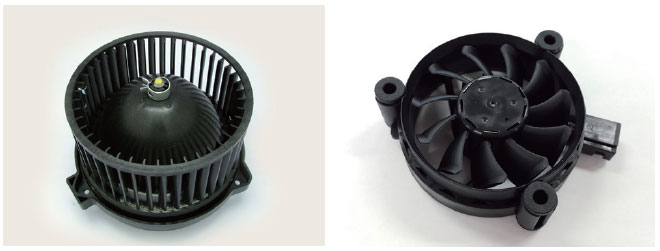

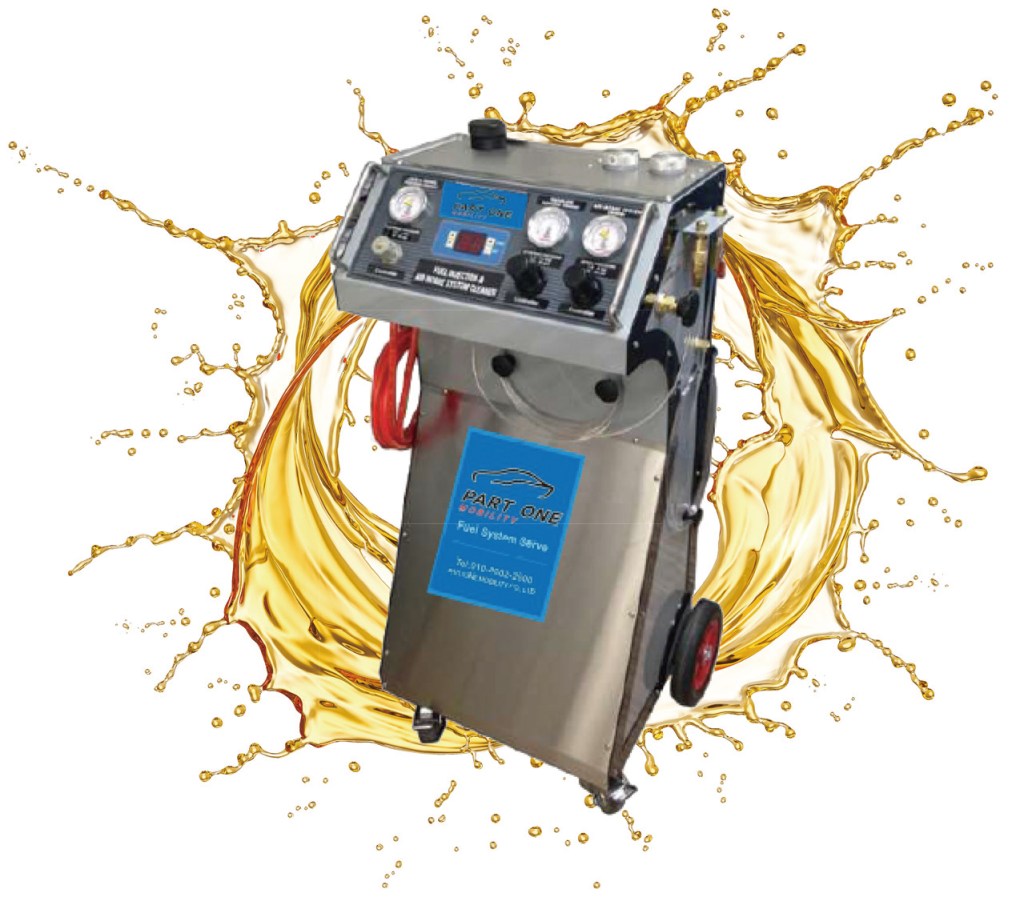

JWON PROTECH’s injector-cleaning device, Fuel System Serve, is available for gasoline and diesel vehicles and can be easily connected to the fuel line for use.

Instead of diluting the fuel, the company’s powerful chemicals start and clean the engine, providing feedback of light and powerful output increase after they begin to work.

This device intensively cleans fuel deposits and foreign substances that accumulate in common-rail diesel injectors. It addresses issues such as reduced output, reduced fuel efficiency, increased exhaust emissions, and poor starting.

Washer

The K1 washer is larger than standard washers. While used in a variety of locations, including auto repair shops, bike shops, and industrial plants, it still provides enough space to clean most parts.

The device is designed to allow the operator to work while standing up without bending. The wash tank is easily accessible for cleaning after multiple uses, allowing for a clear view of the tank when changing the detergent.

The pressure spray nozzle is divided into two types: a front-mounted nozzle; and a hand-held high-pressure hose nozzle.

When cleaning small parts, it is convenient to hold the part with both hands and spray high-pressure water from the front-mounted nozzle. The hand-held high-pressure hose nozzle allows the worker to view and clean every nook and cranny of the part. The front view is secured by reinforced glass with an air curtain inside, which sprays air during work to help secure the worker’s view.

The interior work light is not installed inside the vehicle, but rather shines inward from the outside of the tempered glass. Since the work light does not stick to dirt and debris, proper windshield maintenance ensures long-term visibility.

Petrol System Cleaner, Pre-Mix

JWON PROTECH’s petrol system cleaner, Pre-Mix, cleans gasoline injectors and restores their injection patterns. It safely and effectively cleans the inside of the combustion chamber, and also adds safety features to various catalysts and sensors.

Diesel System Cleaner, Pre-Mix

JWON PROTECH’s diesel system cleaner, Pre-Mix, cleans diesel injectors and restores their injection patterns. It contributes to engine power restoration and smooth idling. It also helps reduce engine noise and vibration.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods