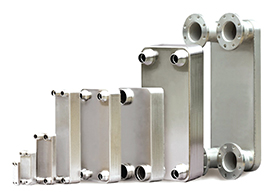

Installing a compact brazed plate heat exchanger leads to an 85~90% reduction in the volume and weight of a shell-and-tube exchanger of the same capacity.

Installing a compact brazed plate heat exchanger leads to an 85~90% reduction in the volume and weight of a shell-and-tube exchanger of the same capacity.

Features of high working temperature (+185C), high working pressure (180kg/cm), low working temperature (-160C), and low working pressure (2×10-5 Torr, vacuum) are available.

A brazed plate heat exchanger is made of stainless steel AISI 316L in order to withstand tough demands. The compact and smooth surface and design makes it easy and cost-effective to insulate.

Since its founding in 1985, Dongil Brazing Co., Ltd. has been focusing on the plate heat exchanger and D-MAX boiler. All employees are certified technical masters, engineers, and technicians and working hard with pride to produce world-best products. The R&D center spares no effort for R&D. The plant produces the best quality products. The offices around Korea provide perfect sales plans and A/S to give customers complete satisfaction.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods