HANSBAR is the brand name of cast iron bars produced by HANS Materials Inc. since 1991 through a horizontal continuous casting process.

Due to the dense microstructure and the extreme suppression of defects, HANSBAR shows superior characteristics when compared to conventional sand-casting products. Furthermore, when compared to steel with similar mechanical properties, it delivers excellent machinability, with superior noise and vibration characteristics.

HANS Materials seeks continuous improvement and innovation to ensure world-class products. This, combined with strict adherence to basic production principles and dedication to satisfying the customers, ensures the high integrity of HANSBAR.

The molten iron held in the concast holder provides a large head of iron above the graphite die, thus reducing the risk of internal shrinkage defects in the pulled bar, whilst also allowing the lighter impurities in the iron to float upwards in the holder. This ensures homogenous material properties in the finished product.

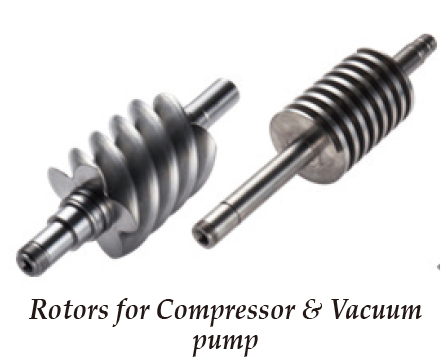

Due to its excellent quality and mechanical properties, HANSBAR is being applied to critical components across various industries – such as for pneumatic and hydraulic parts, rotors for high vacuum pumps and compressors, gears and shafts for automobiles. By adopting HANSBAR in your products you will immediately increase your competiveness in your market.

HANSBAR is produced in round, square or rectangular shapes. HANS Materials Inc. is the only manufacturer of continuous cast iron bars in South Korea, and as such they can be produced and supplied according to the material properties and sizes required by the customer.

A spokesperson for the company commented, “Our technical team will suggest the optimum solutions to your problems.”

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods