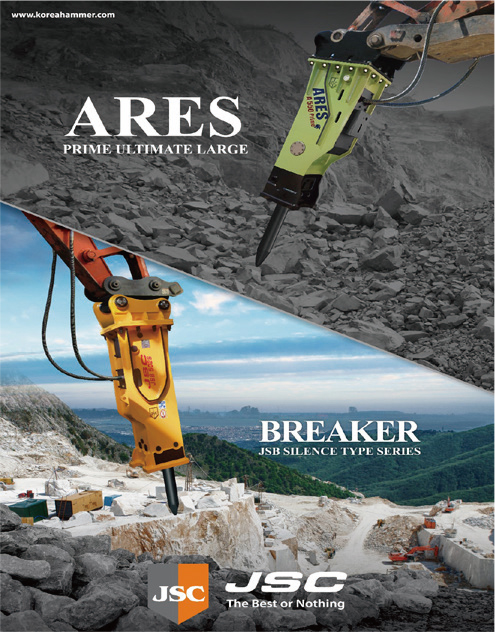

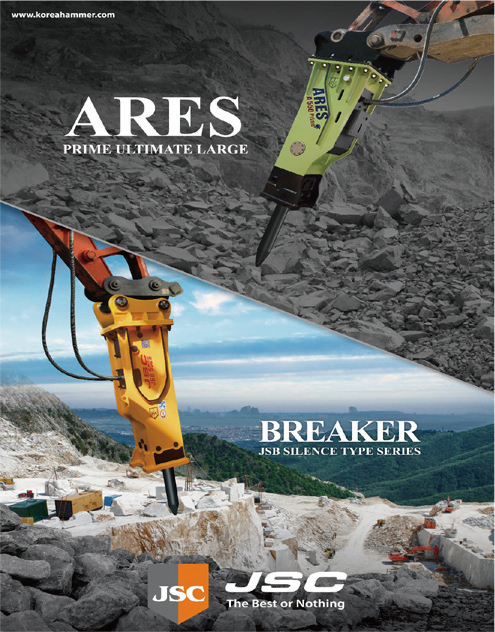

[INQ. NO. 2402M07] Hydraulic Breaker

A hydraulic breaker is a powerful percussion hammer fitted to an excavator as the core attachment for demolishing concrete structures or rocks. The applications for a hydraulic breaker include rock breaking, slag breaking, reducing oversize materials, concrete breaking and recycling, site excavation, construction & demolition recycling, sorting, scaling and tunnel excavation, and trenching.

JSC’s hydraulic breaker system ensures high impact energy as a combination of nitrogen gas and hydraulic energy provides powerful impact for high-performance strength.

With only two moving parts, the valve and piston, JSC’s breakers are designed for maximum uptime and reliability and reduced operating expenses. It also features up to 30% fewer parts than its competitors, thus reducing operating expenses and maintenance costs.

General Crusher

A general crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.

Crushers may be used to reduce the size, or change the form of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of various compositions can be differentiated.

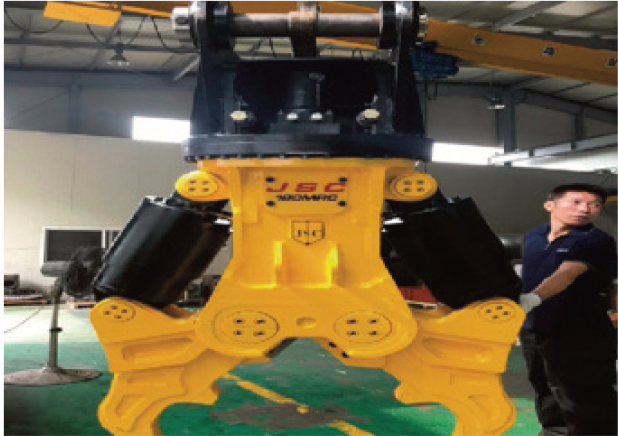

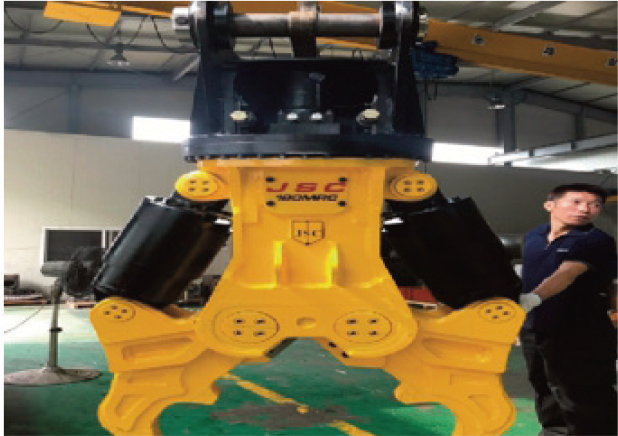

Demolition Attachment

Interchangeable jaws as one of the excavator attachments are perfectly designed for primary & secondary demolition, which applied to various construction sites.

The structure is manufactured from high strength, abrasion-resistant steel for permanent use.

Established in 2004, Jisung Heavy Industries based in Korea started the business and JSC Co., Ltd was spun off from Jisung Heavy Industries in 2010 as an organization dedicated to overseas sales.

JSC has extensive overseas sales experience in more than 30 countries such as USA, Mexico, the Netherlands, Russia, Indonesia and Vietnam, especially for hydraulic breaker products during the past 15 years.

JSC has now covered hydraulic breakers from compact class to heavy-duty class based upon the selection and type of the machine and other attachments mounted on the excavators.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods