Hyunseo Precision Co. has been producing high-quality automotive forged parts and forged molds, with over 30 years of practical experience.

Hyunseo Precision is advancing toward the top in this field through continuously improving quality, processing methods, and mold life ― based on organic harmony from designing and manufacturing forged molds through 2D and 3D.

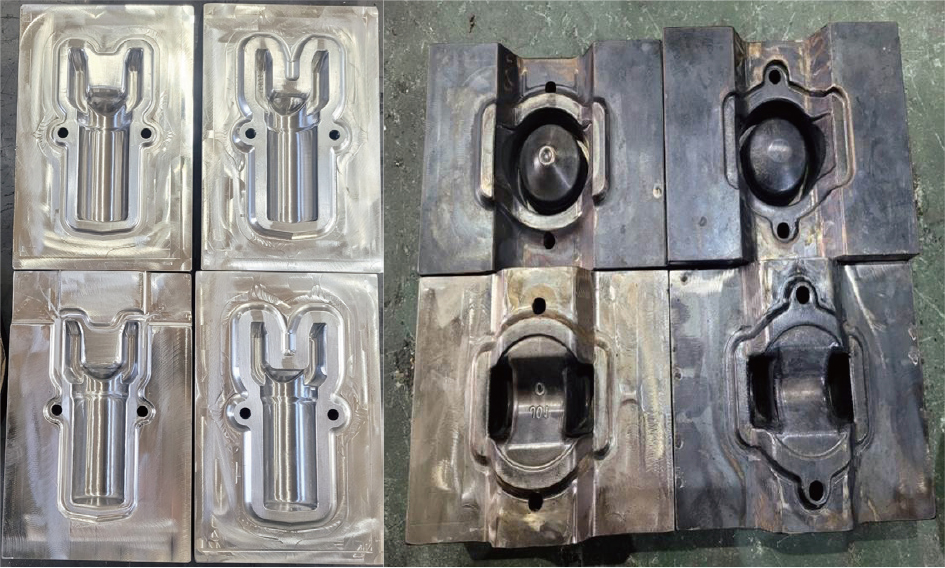

Hyunseo Precision specializes in mold manufacturing of forging parts for automotive steering components, including yokes, tie rods, and ball joints.

Yokes

Hyunseo Precision’s yokes are U-shaped connecting parts used in automobiles, primarily connecting rotating shafts and transmitting power. Yokes are used as joint components connecting drive shafts, universal joints, and in particular the motor output shaft and wheel drive shafts in electric vehicles.

Tie Rods

Hyunseo Precision’s tie rods are key components that connect the steering gear and wheels, transmitting steering power. These tie rods consist of inner and outer tie rods and transmit power to the wheels when the driver turns the steering wheel.

These tie rods transmit power from the steering wheel to the steering gear, tie rods, and to wheels, ensuring flexible connection between the vehicle body and wheels. Thus, these parts contribute to the vehicle’s straight-line stability and the tires’ degree of wear.

Ball Joints

Hyunseo Precision’s ball joints function similarly to the human shoulder joint. These parts help move the wheels to the left and right when the steering wheel is turned by driver.

They also reduce shock when the wheels move up and down due to bumps in the road, thus providing stability to the wheels and vehicle body.

Hyunseo Precision’s strength lies in its advanced aluminum forging mold manufacturing technology, which enables the development of aluminum parts for lightweight electric vehicle (EV) components.

Aluminum parts are approximately one-third lighter than steel, contributing to improved fuel efficiency and longer EV driving range. They also reduce carbon emissions and resist surface oxidation (rust), providing high durability without the need for painting or plating. Furthermore, they are lighter than steel while maintaining strength, lowering the vehicle’s center of gravity and enhancing driving stability.

“Going forward, we will continue to respond to customer requests with a stable company system through mold life, productivity and quality improvement, and develop into a company that leads customer satisfaction,” remarked the company’s CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods