Turbolink Co., Ltd. is a leading manufacturer of fluid film bearings for high-speed rotating machinery.

Since its establishment in 2001, through continuous R&D – from bearings of high-speed turbo compressors, to high-load turbines and generators with axial loads of hundreds of tons – Turbolink has been developing various product lines with its own technology.

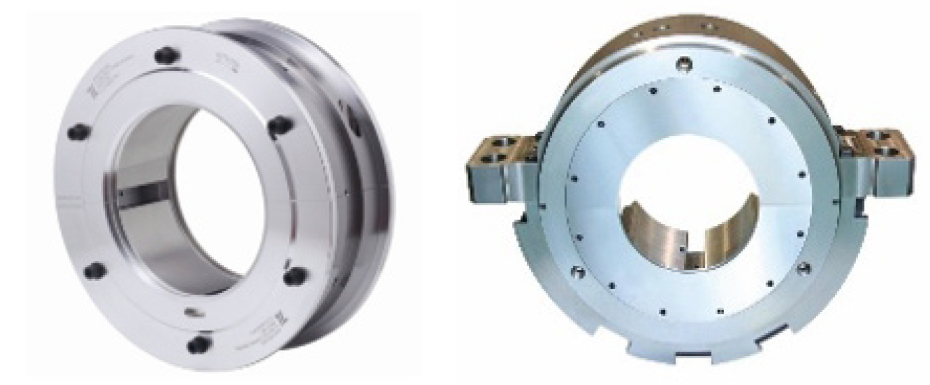

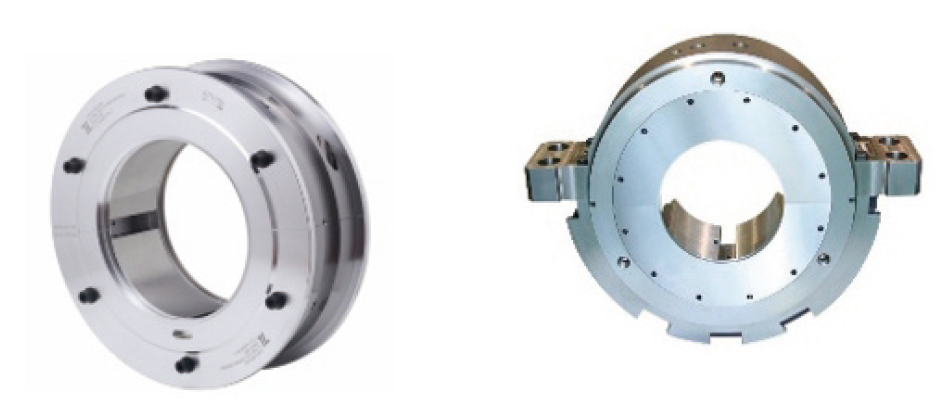

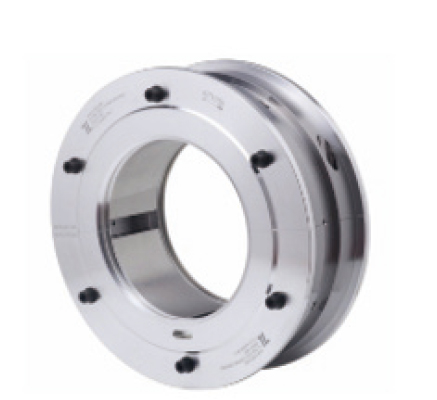

Tilting-pad Journal Bearings

Tilting-pad journal bearings are widely used in high-speed rotating machines due to their high dynamic stability, damping characteristics, ability to operate at high rotational speeds, and long service life.

Tilting-pad journal bearings are used for steam turbine/generators, gas turbines, turbo-compressors, hydraulic turbine/generators, high-pressure pumps, and high-speed gear systems.

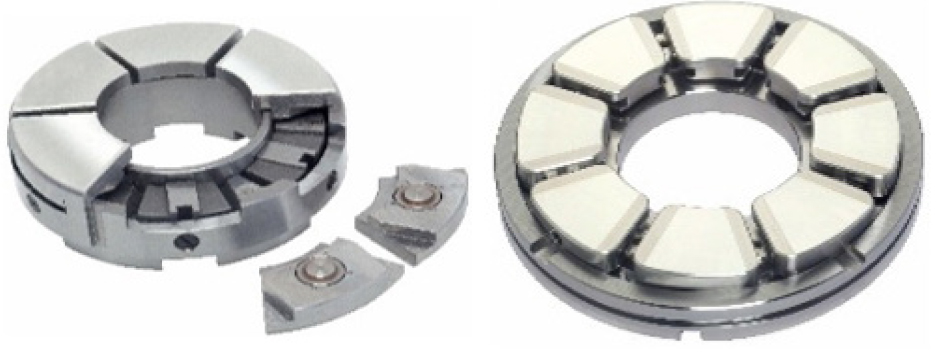

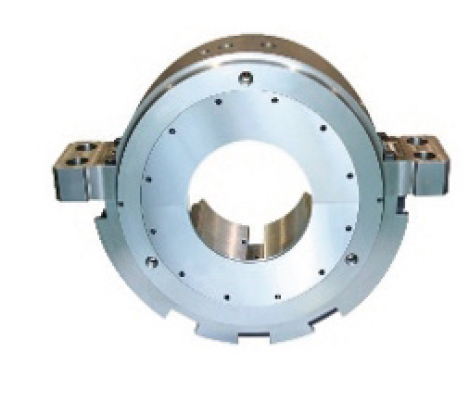

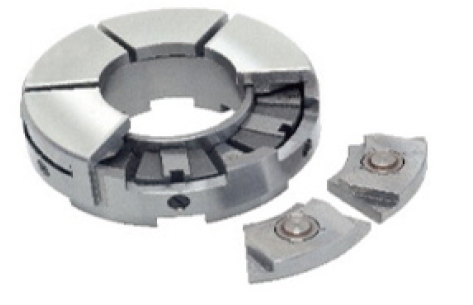

Tilting Pad Thrust Bearings

Tilting-pad thrust bearings are designed to transfer high axial loads from rotating shafts with minimum power loss, while simplifying installation and maintenance.

Tilting-pad thrust bearings are used for steam turbine/generators, gas turbines, turbo-compressors, hydraulic turbines/generators, high-pressure pumps, and high-speed gear systems.

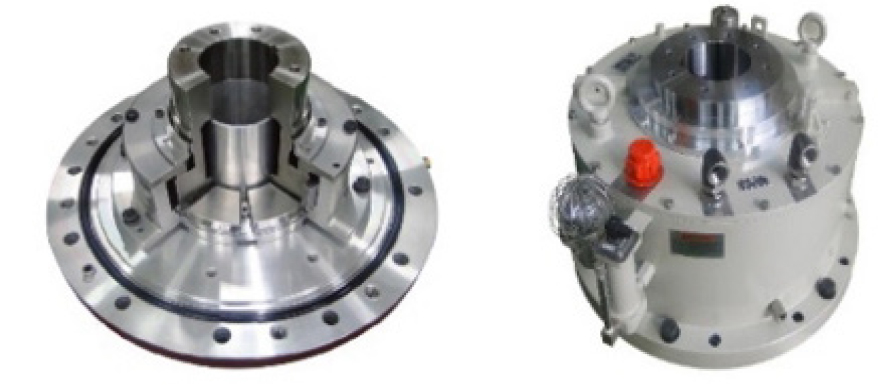

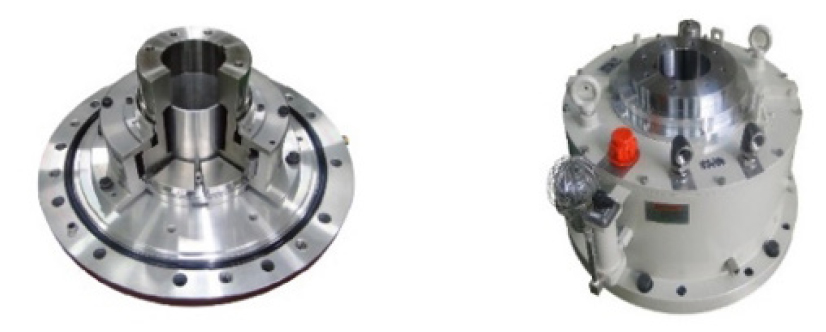

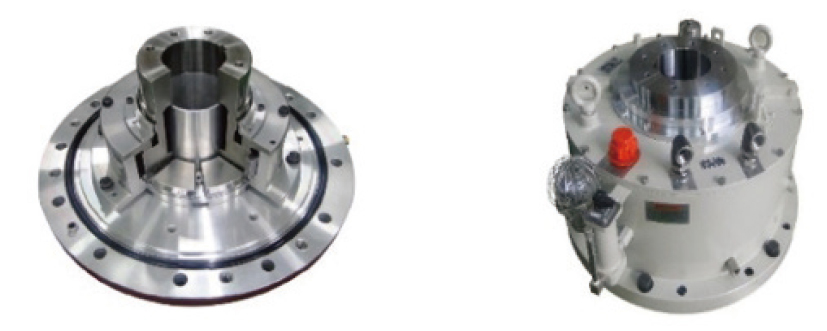

Vertical Bearing Assemblies

Turbolink’s vertical bearing assemblies of self-contained thrust and guide bearings offer proven bearing solutions for vertical machines, motor, pumps, or hydraulic turbine-generators.

With more than 21 years of proven service, Turbolink’s vertical bearing assemblies are available in a wide range of sizes and include a variety of innovative design options, including various cooling arrangements, electrical insulation, hydrostatic lift provisions and instrumentation.

The vertical bearing assemblies are applicable for hydraulic turbines/generators, vertical motors, and vertical pumps (CEP, CWP, SLP, etc.).

“We built a new factory with a total area of 6,600 square meters in Korea in 2013 as part of our efforts to become a leading company in the global market that customers seek first, and we are ceaselessly focusing on R&D and quality improvement,” remarked a spokesperson for the company.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

The mast roller bearings are used in heavy duty and shock loading to the Guide Roller during the vertical movement. And it is designed a suitable structure for forklift Mast. A deep groove ball bearing made of special applications. The load capacity is 0.5ton (1100 lb) ~ over 25ton (55,110 lb) for forklift mast.

The mast roller bearings are used in heavy duty and shock loading to the Guide Roller during the vertical movement. And it is designed a suitable structure for forklift Mast. A deep groove ball bearing made of special applications. The load capacity is 0.5ton (1100 lb) ~ over 25ton (55,110 lb) for forklift mast.