[INQ. NO. 2310M02] Established in 2013, DAESUNG HITECH Co., Ltd. is the only domestic manufacturer that directly develops, designs, and sells grinding machines and vacuum cleaners based on the know-how acquired through many years of the building of construction sites.

DAESUNG HITECH has multi-patented grinding machines, which have a domestic market share of over 70%. It grew steadily and became an export company in 2014 through expanded overseas marketing thanks to the expansion of the trade department.

DAESUNG HITECH researched and developed the first automatic vacuum cleaner with a function of filter duster at home and abroad, and applied for a domestic patent and a U.S. patent in 2019, thereby currently growing as an export company with increased export volume.

Automatic vacuum cleaner (Y-3700AHL) with filter duster

DAESUNG HITECH’s latest automatic vacuum cleaner with a filter duster function, Y-3700AHL, is now available in Korea. As the first patent-applied vacuum cleaner, it is an industrial vacuum cleaner that can be used in all sites such

as construction, industry, and factories where flying dust, fine dust on the floor, or dust is generated.

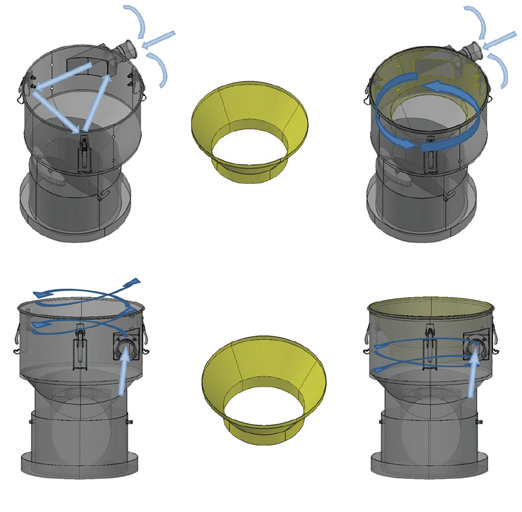

Y-3700AHL, equipped with a reverse flow prevention cap to extend the life of the motor and a cyclone cover to protect the filter from dust generated when entering the interior, minimizes the damage to the motor and filter, extends its lifespan, and enhances the suction power.

Y-3700AHL features a bristle rod that rotates inside the filter and strikes the filter to shake off dust. By minimizing the dust that sticks to the filter, it can be used for a long time by maintaining three- to five-times the suction power of existing manual vacuum cleaners. It is used in many fields because it maintains overwhelming suction power and has a much higher work usage time.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods