[INQ. NO. 1503M18] Il Jin Delta Co., Ltd. was established in 1985, and specializes in the development and manufacture of plastic injection mold plastic parts and plastic products. Products developed by Il Jin Delta are widely used in automobiles, bicycles, and household appliances. The company is equipped with a 2,600 square meter factory with advanced equipment to ensure precise manufacturing. The main equipment are CNC discharge machines, drilling machines, grinding machines, injection machines and other processing equipment. Also, in the mold-making and molding processes, Auto CAD, Pro/E, UG, solid works, cimatron and masterCAM are applied. The engineers and the technicians of Il Jin Delta have more than 15 years of experience in the field, which enable precise and efficient manufacture. Currently, products of Il Jin Delta are supplied to leading global companies including LG Electronics, Mazda, Nissan, and Honda.

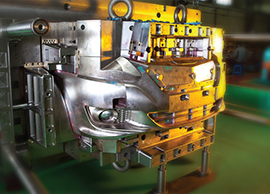

The injection mold developed and manufactured by Il Jin Delta is used for automobile parts and washing machines. From R&D, drawing, mold producing to test, one-stop solution is provided. The injection mold for automotive parts is supplied to domestic and overseas market.

The injection mold developed and manufactured by Il Jin Delta is used for automobile parts and washing machines. From R&D, drawing, mold producing to test, one-stop solution is provided. The injection mold for automotive parts is supplied to domestic and overseas market.

The production of injection molds includes radiator grills radiator tanks, battery boxes, side sills, trunk ends, door trims, grove boxes, spoilers, and bumpers. The injection mold for the washing machine include tub outer covers, base cabinets, top covers, and door frame outers. Also, special injection molds such as tandem molds and stack molds are developed and manufactured. The technologies of the tandem mold and stack mold are possible to meet the customer demands for productivity improvement and increases sales by 30%. Moreover, large molds and industrial machine parts processes are provided, including the rotor shaft, mold, integral forging, wicket gate, and the runner blade.

Iljin has grown in leaps and bounds to become a major automotive parts company. Iljin Delta was appointed a promising company by Kookmin Bank and Busan Bank, and certified with ISO 9001 with exports amounting to US$300 million in 2006.

Iljin has grown in leaps and bounds to become a major automotive parts company. Iljin Delta was appointed a promising company by Kookmin Bank and Busan Bank, and certified with ISO 9001 with exports amounting to US$300 million in 2006.

Its main business segment is the injection mold and machining with products like CNC boring, MCT milling, Machining Center, NC milling and Radial, Lather, die spotting, sawing machine, hoist and EDM. Its overseas market mold purchaser includes Japan’s Takkai Delta, Dec, Maeda, Lexus, Honda, Mitsubishi parts, China’s LG EPN, Thailand’s LG ETH and many others.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods