[INQ. NO. 2506M02] DAEGUN TECH Co., Ltd. manufactures and sells metal 3D printers (PBF method) directly to clients in Korea. It has succeeded in domestic production with the most advanced technology in Korea.

DAEGUN TECH has a proud track record of selling equipment in various fields such as schools, research institutes, and companies. In particular, it has the ability to produce large metal 3D printer equipment (800800800mm) that can be used in the defense, aerospace, and automobile industries.

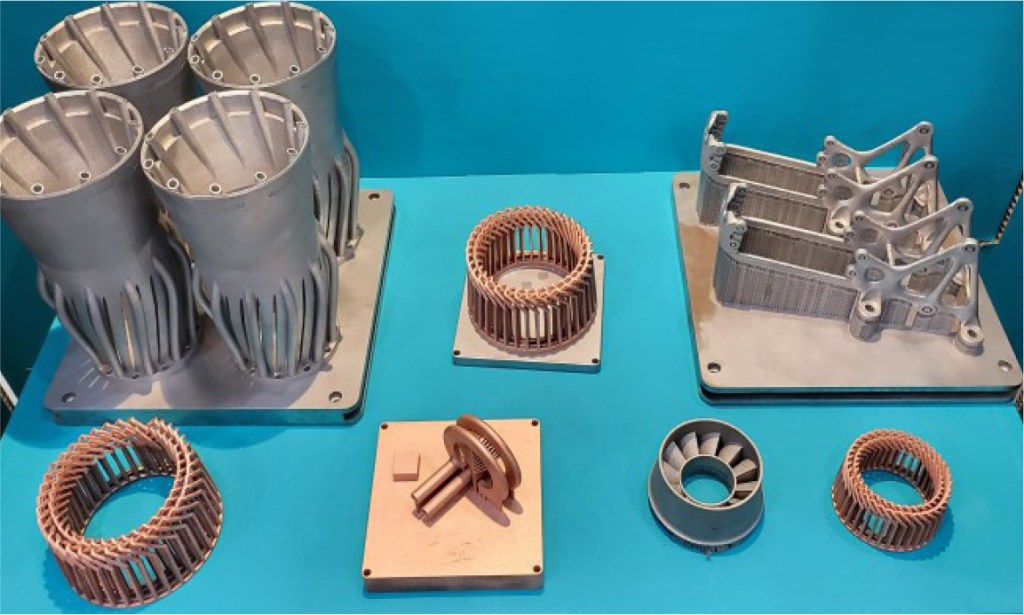

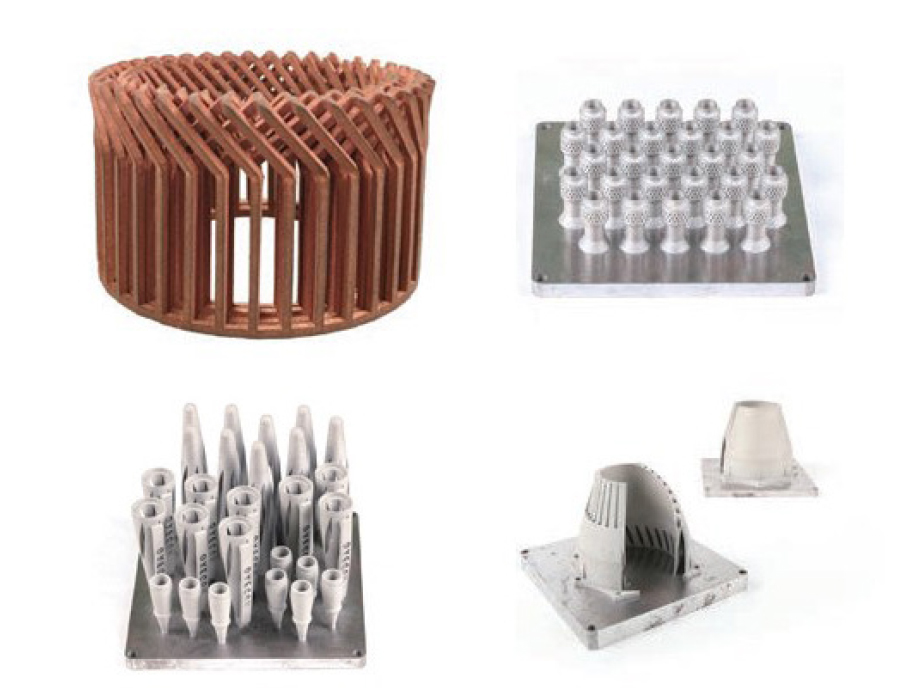

It can thus be seen that the fields in which metal 3D printer technology is applied are very diverse. In particular, DAEGUN TECH manufactures cooling coils and heat exchangers required for high-frequency cooling devices using copper materials. In addition, there are many cases of its technology being applied to manufacturing parts for the defense industry using various materials such as aluminum and titanium.

For low-volume production needs ― such as mockups, prototypes, or single-use exhibition models ― 3D printing offers significant cost savings, especially when mold fabrication would be prohibitively expensive. It is a fast and economical solution, not only for simple models but also for complex geometries or multi-part assemblies that require functional testing.

Domestically in Korea, DAEGUN TECH’s service is recognized for its speed, high precision, and flexible post-processing capabilities. Backed by years of international export experience (e.g., cable harness products), DAEGUN TECH is well-versed in handling overseas orders with a deep understanding of export requirements and the ability to respond flexibly to international project needs.

“We’re aiming to unveil our attractive new metal 3D printer to potential buyers, in addition to further elevating the presence of our competitive existing export items at the upcoming M-TECH Tokyo 2025. We’re proud to introduce these new export items, which are expected to catch keen attention of many viewers. And we hope to make visible business deals at the exhibition,” explained a spokesperson for the company.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

(Fused Deposition Modeling) method, which showed a limitation when applied to metal. This technology that makes metal powder and binder like clay by mixing them will make it difficult for the parts to be realized when the CNC is to be replaced.”

(Fused Deposition Modeling) method, which showed a limitation when applied to metal. This technology that makes metal powder and binder like clay by mixing them will make it difficult for the parts to be realized when the CNC is to be replaced.”