If you are driving in Korea, it is likely that you are in a Hyundai/Kia car. It is even more likely that you have stopped at a petrol station and have opened the oil cap. Then, it is highly possible you have contacted Mando’s product.

If you are driving in Korea, it is likely that you are in a Hyundai/Kia car. It is even more likely that you have stopped at a petrol station and have opened the oil cap. Then, it is highly possible you have contacted Mando’s product.

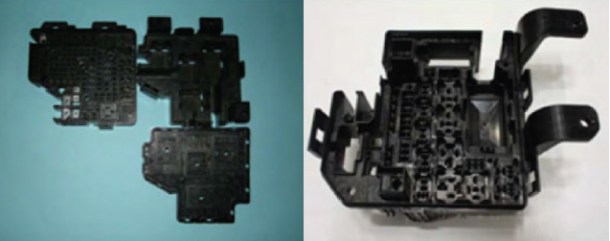

Despite the fancy names like TB120G30, SEPAZ con-E, MPPO and Compound-PP, the products of Mando Advanced Material are everywhere. They are in the engines,

safety devices, cooling systems and chasis of motor vehicles, many electric devices, leisure/sports equipments, furniture, interior design and uncountable industrial items.

The 11,600m2 plant in Hwaseong has been where Mando’s polymer materials have been studied, researched and created since its establishment in 2005.

The polymer makers do not only have broad and streamlined production systems but also a highly efficient and successful research center. Though its short history of a decade, the research center gave birth to PA6, PA66 GF strengthened plastic products, PA6, PA66 high-impact and super high impact products, high-strength and scratch-resistant composite PP, high-impact PC/PBT alloy products, high-impact PC/ABS alloy products, olefin-based flexible products, low-distortion and heat-resistant composite PP products, highly flexible and low-distortion composite PP products, PBT and PET products, PET/PBT alloy products, PA/ABS alloy products, PA/PPO alloy products.

On the basis of the extensive knowledge and experience, Mando is now focusing on various high-performance alloys, including nanocomposite polymers and high-valued elastomers.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods