[INQ. NO. 2407M09] Innochem Co., Ltd. is specialized in the manufacturing of long-term corrosion prevention coatings and sealing solutions on buried and exposed steel pipelines.

The company’s wide range of products caters to diverse sectors including oil, gas, water supply, chemical, and infrastructure, etc.

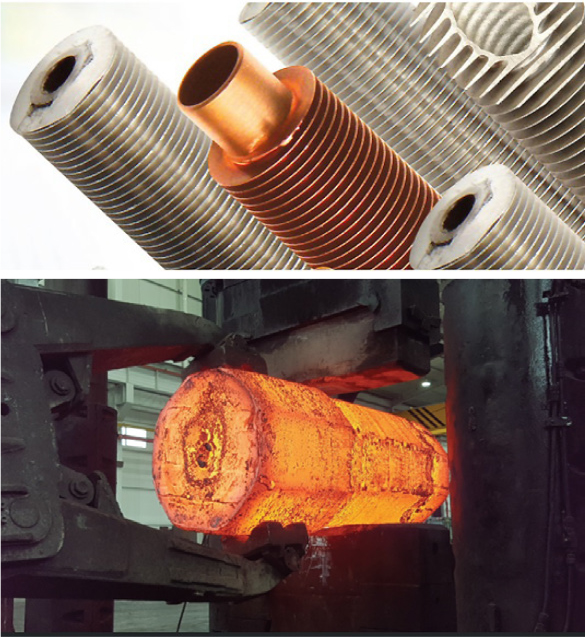

Currently it mainly produces three major products: cold applied tape system; heat shrinkable sleeve; and irrupted heat shrinkable casing system.

The cold applied tape system (Innowrap) is specifically designed to combat corrosion in various pipe mainlines and fittings such as field joints, elbows, tees, and valves, etc.

The heat shrinkable sleeve (Kowrap) is engineered for corrosion protection, employs powerful heat shrinkage force, and self-healing effect for application on buried and exposed steel pipelines.

The irrupted heat shrinkable casing system (Innoplus) serves as a premium finishing material for pre-insulated pipelines.

Committed to customer satisfaction, Innochem offers tailored design, manufacturing, and technical support, ensuring adherence to global quality, environmental, and safety standards.With a relentless focus on research and development, Innochem is strengthening its global foothold, prioritizing uncompromising quality in every endeavor.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods