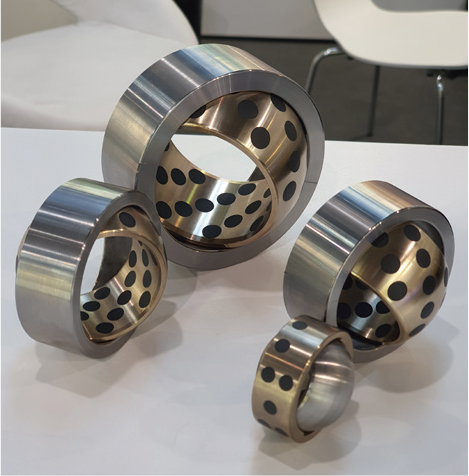

Oilless bearing manufactured and supplied by HANKOOK MATERIAL Co., Ltd. is a bearing that can promote improvement of a machine’s performance, reduction of fueling manpower and cost, and productivity improvement by realizing oilless conversion on parts where fueling is impossible or ineffective due to high load, low speed, low temperature, corrosive atmosphere, foreign substance inflow, impact load, vibration, and structure.

The applicable materials and shapes of the company’s oilless bearing vary depending on the conditions of use, from metal, copper, Teflon, and ceramics to high-functional plastic.

Necessity of oilless bearing

It has various materials and shapes, so it can be used instead of balls and roller bearings for parts where they cannot be used.

It can prevent a decline in productivity caused by the shutdown of a machine when fueling.

Advantages of dry sump lubrication (use of solid lubricants)

It can be used at low and high temperatures. It can also be used in corrosive atmospheres. It is perfect for slow motion of high loads, reciprocating motion, impact load, angle shaking motion, and discontinuous multiple stop motion. It can be used 100% oilless.

HANKOOK MATERIAL is developing and producing competitive products by constantly investing and developing, so their products can be supplied and applied not only to domestic auto, industrial machinery, and machine tool industries, but also throughout industrial machines, heavy equipment, and molds in Asia and Europe.

The CEO of this company emphasized, “We will keep doing our best to be a company developing together with our customers by providing high-quality systems through constant R&D and investment.”

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods