SAMYOUNG FITTING Co., Ltd. was established in 1989 and has been working on a single manufacturing technology for some 30 years, gaining a leading position as a global supplier both at home and abroad thanks to its outstanding technology.

SAMYOUNG FITTING is responding to current market conditions through the diversification of its customers and technologies.

Through continuous development, the company is able to stably extend, supply, and meet the gradually increasing demands of both domestic and overseas markets, and newly acquired customers.

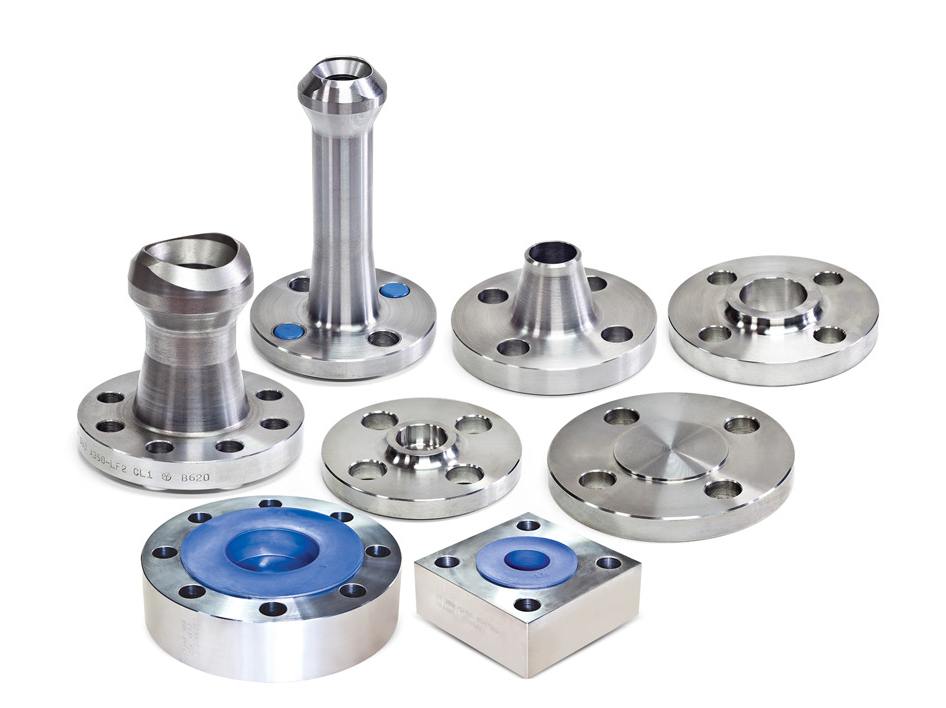

Pipe Connectors Based on International Standards

SAMYOUNG FITTING mainly manufactures pipe connectors such as forged fittings, sleeves, flanges, etc., in accordance with international standards (ASTM, ASME, BS, JIS, ANSI, MSS, etc.).

SAMYOUNG FITTING is continuously providing different product groups for each of the following industries: nuclear power plants; shipbuilders at home and abroad; offshore; chemical companies; oil refineries; and constructors.

SAMYOUNG FITTING supplies custom-designed drilling & machining equipment for forged fittings, elbows, tees, automatic machining technologies, deep hole processing machines used to produce sleeves and atypically-sized pipes for the marine shipbuilding industry, high-speed cutting technology for large-sized pipes, and other core technologies.

Carbon steel, alloy steel, stainless steel, duplex steel, ni-base alloy steel, Cu-ni alloy, titanium and other materials are used for such products.

Founded in 1989, SAMYOUNG FITTING has evolved from being a local specialist to a global player. SAMYOUNG FITTING is a premium supplier of forged-fitting in the field of power plants, oil & gas, offshore, and the shipbuilding industry. It offers its customers outstanding products by applying its complex technologies.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods