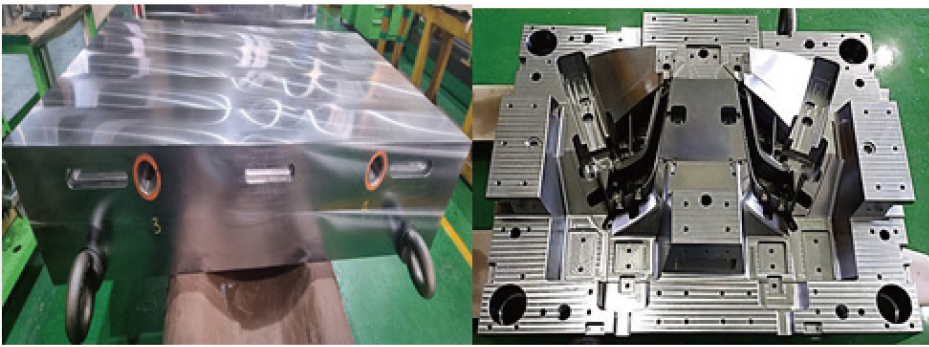

Plastic Injection Molds

Since 1990, Miju Precision has specialized in manufacturing plastic injection molds, backed by over 30 years of unparalleled expertise as a leading company in Korea. The company prioritizes customer satisfaction by delivering cost-effective, high-quality products with fast turnaround times.

One of Miju Precision’s greatest strengths is its fully integrated in-house process — from design and mold manufacturing to trial injection molding using machines ranging from 150 to 2,000 tons. This allows the company to test and verify each mold’s performance before delivery. Its advanced design and machining capabilities, combined with rigorous multi-stage quality control, enable the company to produce molds of exceptional precision and complexity, ensuring defect-free results.

With a sales office and dedicated mold maintenance facility in India, Miju Precision are able to strengthen its global competitiveness by collaborating closely with customers worldwide. This presence allows Miju Precision to better understand international market needs, respond quickly to customer requirements, and maintain an efficient global supply chain.

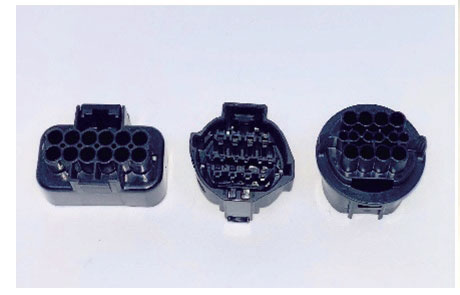

Miju Precision provides molding solutions across diverse industries, including automotive, home appliances, electronics, medical devices, and consumer goods. By continuously advancing its technology and craftsmanship, Miju Precision grow alongside its customers as a trusted partner delivering value worldwide through cutting-edge solutions.

Founded in 1990, Miju Precision Co., Ltd. aims to become a global leader in injection mold manufacturing through relentless commitment to quality, innovation, and customer satisfaction.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods