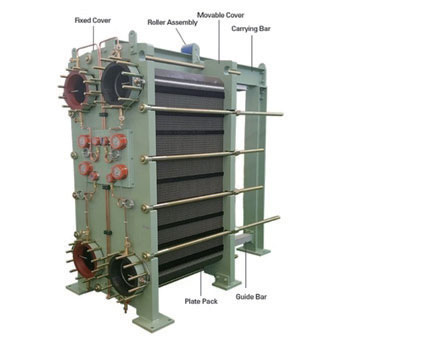

[INQ. NO. 2010M33] LHE’s plate heat exchanger consist of heat transfer plates for exchanging heat, gaskets that seal the fl uid fi xed and movable covers, fl uid inlet & outlet port nozzles, carrying & guiding bars and tightening bolts.

The key element of the plate heat exchanger is a hydraulically-pressed metal plate with a thin rectangular plate, gasketed at the edges.

Several heat plates are overlapped to form a single pack and bolted between the fixed and movable covers. The gasket installed on the heat plate prevents the mixture of the two fluids and leaks out of the plate pack to the surroundings.

Each pair of adjacent heat transfer plates forms a channel and hot fl uid and cold fl uid fl ow within that channel. While two fl uids pass through the channel hot fluid transfer some of its heat energy to cold fl uid in the other channel through the thin plate. As a result, it reduces the temperature of the hot fluid and increases the temperature of the cold fluid.

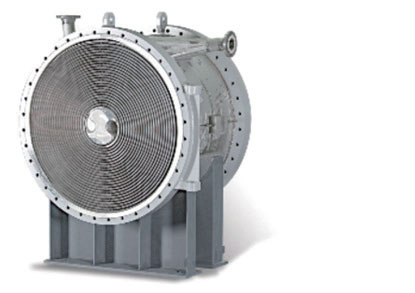

LHEBloc’s main component is the plate pack, panels, panel gaskets, upper & lower heads, columns and support.

LHEBloc is manufactured by inserting a welded plate pack into a rigid rectangular frame secured with bolts and has the advantage of providing a large heating area even in a very small space. The frame ensures mechanical strength while also insolating the fl ow paths of the two fluids.

If necessary, each flow path is fitted with a welded or detachable baffle. Four side carbon steel panels with nozzles attached have pipe connections and the panels can be lined with the same material as the heat plate. The plate, baffle and panel liner are made of stainless steel, titanium, etc. A pair of heat plates is welded along both ends.

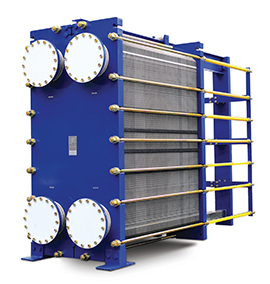

The spiral heat exchanger is made of two concentric channels in which spacer pins are welded to create the gap of the channel. In order to meet the customer’s requirements and operating conditions, channel spacing and channel width are determined, and the overall flow rate allowable pressure drops, and the particles contained in the fluid should be considered.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods