[INQ. NO. 2512M08] MiKwang Machinery Co., Ltd. supplies high-quality machinery based on its accumulated technology and experience, ranging from specialized textile machinery processing equipment to industrial coating, drying, and film processing.

Since its founding, MiKwang Machinery has continuously strived to meet the needs of its customers. MiKwang Machinery will continue to be the best partner in improving the quality of its customers’ products and enhancing their competitiveness.

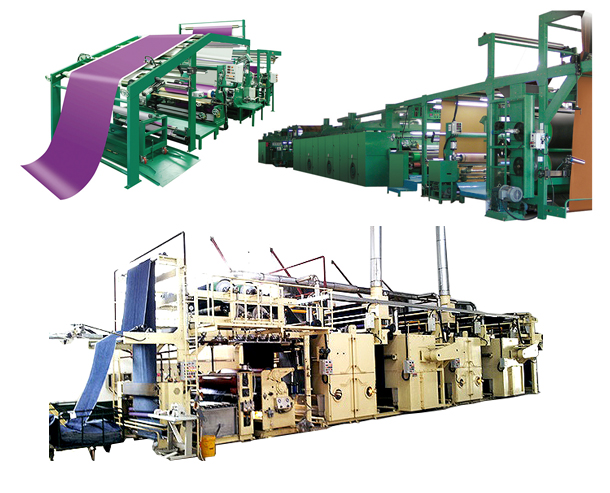

Mega Calender Machine

MiKwang Machinery’s mega calender machine is a machine for high-gloss fabrics. The computerized rotation speed of the upper and lower rolls allows for easy operation. It can be widely used for multi-purpose calendering, such as calendering high-gloss fabrics, and shirring. By replacing the upper roll with a steel roll, it can also be used as a calender shoe liner.

Mega Steamer Machine

This machine offers selective operation at high and low temperatures, thus reducing heating and cooling times (saving energy and costs).

This machine features a dramatically improved humidifying system and maximizes uniform production. It has a complete hardware system to prevent damage from heat and contamination. It is corrosion- and defect-free, and is easy to operate. It also permits satisfactory maintenance.

Mega Coater Machine

This machinery enables uniform coating through precise tension control. Furthermore, it is possible to control tension for each device and is designed to prevent overtension of the coating fabric structurally.

Mega Laminating Machine

This machine is a coating & laminating device for synthetic leather and highly functional outdoor products. Uniform and precise item manufacturing work for the film thickness of 0.001m/m is available without deviation on the left and right. It delivers outstanding performance for the work of highly functional items (waterproofing & moisture movement).

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods