[INQ. NO. 2401M01] The ‘Optical Coherence Tomography (OCT)’ technology used in the medical field has been expanded to industrial use. This technology identifies defects by penetrating inside the semiconductor and display.

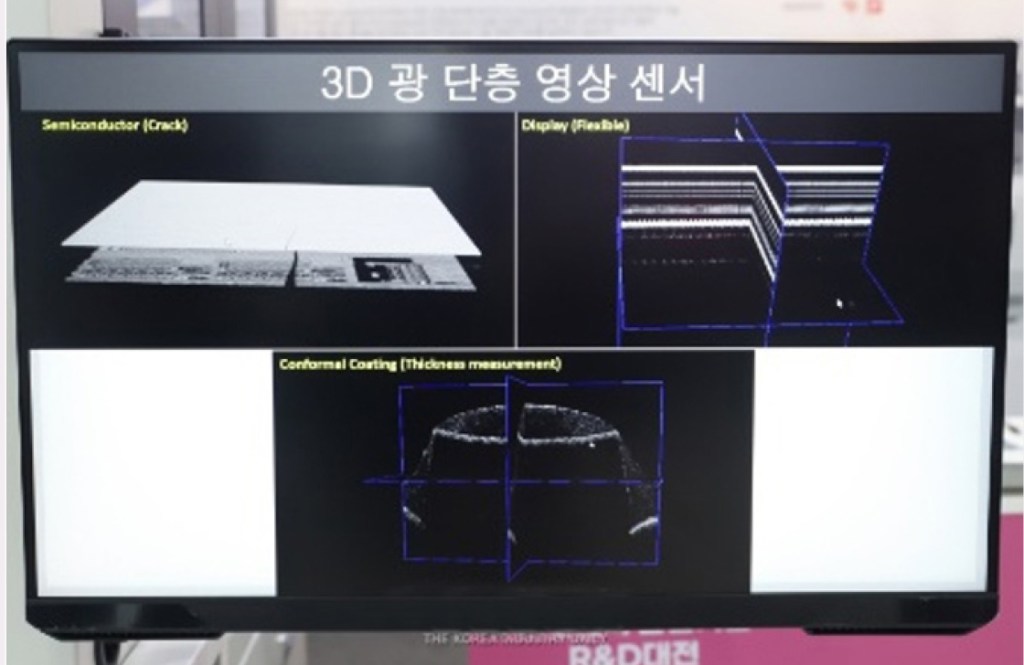

MVTech Co., Ltd., a machine vision company, introduced its ‘3D optical tomographic inspection equipment’ at the recently held 2023 Korea Industrial Technology R&D Expo.

OCT is technology that obtains high-resolution tomography images by using the time difference of the reflected light transmitted. A spokesperson for the company explained, “We acquire images using the different properties of the index of refraction of reflection and transmission according to the wavelength of light.” Like an X-ray, it can penetrate inside the product to inspect cracks, foreign substances, scratches, coating thickness, etc., and find defects in mobile phone displays or semiconductor wafers.

Even microscopic defects are fatal in high-tech components such as semiconductors and displays. In general, X-rays were used in the production process to read, but the use of radiation was dangerous and had low resolution.

MVTech’s 3D optical tomography imaging inspection equipment acquires high-definition images up to 2.5μm (micrometer). The tomographic image can be reconstructed in 3D and viewed at a glance.

This equipment can penetrate any surface to accurately determine the size and thickness of materials in each layer, and also detect internal defects. This product can be connected to existing inspection processes to identify defective products and take action.

A spokesperson for the company commented, “It is not yet in the commercialization stage, but we have completed development and are reviewing the technology with major companies,” adding, “It is suitable for inspection of transparent and translucent materials that allow light to pass through, so we are approaching it as equipment specialized for semiconductors and displays.”

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods