[INQ. NO. 2211M09] In 1984, Komas Co., Ltd. launched its business specializing in industrial packaging peripheral and later, became the first and best manufacturer of industrial thermoforming vacuum packaging machine in KOREA.

SANVAC® is the manifestation of their principle, “Our machines for reliable and durable performance”. The 2003 prototype is operating still and it will continue its operation in the coming years.

Its dependability comes from pragmatic design, strong frame of qualified stainless steel from POSCO, high-end partial parts inside and assembly by skillful technicians.

Quality has already been verified for decades in KOREA

Over the years, Komas has been growing up with representative food-processors from Korea like CJ Cheiljedang, Dongwon F&B, Hansung Enterprise, Harim, Sajo Daerim, etc. Re-orders are increasing from their experience and confidence.

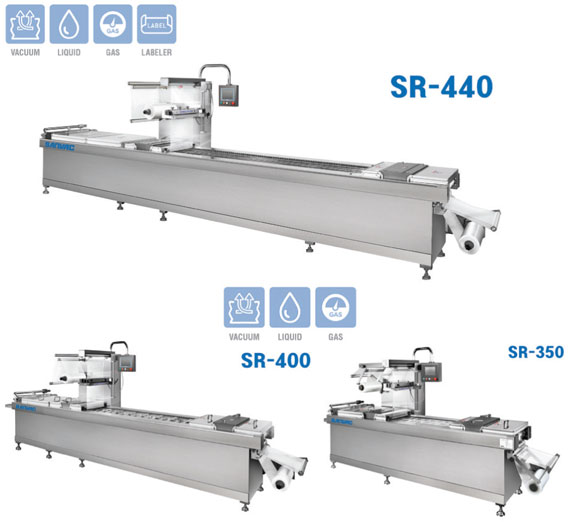

SANVAC® is more than the ordinary in performance, durability and optional functions

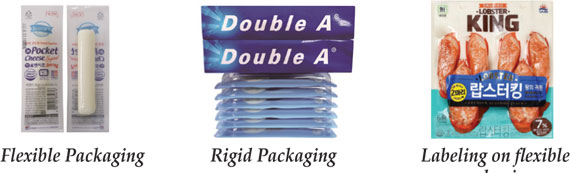

Komas customizes the machine in terms of size, functional option and capacity according to buyer’s requirements. For example, buyers can designate one mode between ‘flexible packaging’ and ‘rigid packaging’ on the biggest model. ‘Rigid packaging’, here, refers to instant thermoforming mechanism without premade trays, capable of 1000 micron of PET or PP film.

It can also customize MAP (Modified Atmosphere Packaging) and/or Liquid Packaging system on both types of packaging.

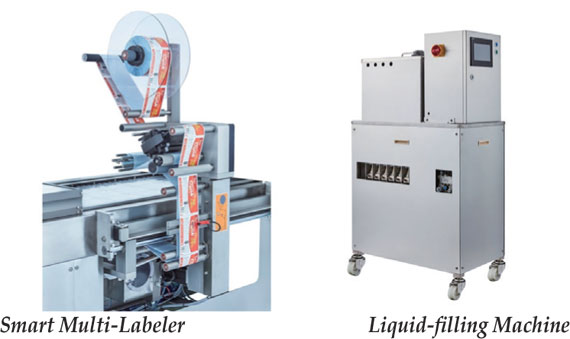

Komas has developed its own labeling machine and liquid-filling machine. It will offer you a one-stop solution of packaging, liquid-filling and labeling. Buyers are free from compatibility or warranty issues which may arise among different manufacturers.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

Jungwoo Motor developed a premium (IE3) class motor industrial motors the production and sales of the existing high efficiency (IE2) industrial motors.

Jungwoo Motor developed a premium (IE3) class motor industrial motors the production and sales of the existing high efficiency (IE2) industrial motors.