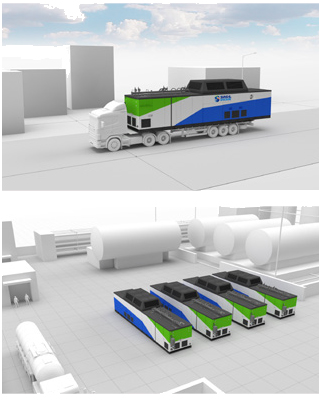

[INQ. NO. 2512M01] Hydrogen, a promising clean-energy source, is currently mostly stored and used in gaseous form.

However, using it as a liquid not only reduces its volume by 1/800, but also offers advantages such as increased transportation efficiency, lower pressure storage, and improved purity. Consequently, many companies are accelerating the development of technologies to store and operate hydrogen in liquid form.

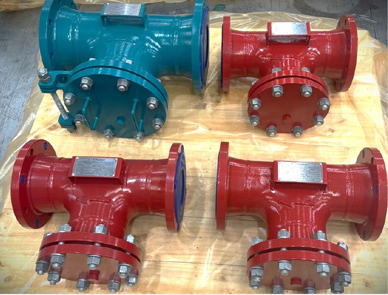

Recently, KwangShin participated in the World Hydrogen Expo 2025 (WHE 2025) held at KINTEX in Goyang, Gyeonggi Province, and showcased a compressor that envisions the era of liquid hydrogen.

At the exhibition, KwangShin unveiled a piston-type compressor for general charging stations used to refuel passenger and commercial vehicles. According to the company, this compressor is capable of high-purity gas compression and high-capacity compression per unit time.

A spokesperson for the company explained, “While fossil fuels have been the primary fuel source, we cannot ignore the issues of environmental pollution and depletion. Regardless of the manufacturing process or method, if we can successfully produce hydrogen, it could lead to the replacement of fossil fuels and ultimately transform the energy industry.”

Since its founding in 1967, KwangShin has dedicated nearly 60 years to the development and manufacturing of compressors. As the first company in Korea to produce and manufacture compressors domestically, KwangShin holds a 50% domestic market share and is a company that received a World-Class product certification by the nation’s government.

In particular, the Current Natural Gas (CNG) compressor, developed in the early 2000s by the company, has been widely used with the introduction of NGV city buses, which compress and refuel natural gas. Since then, it has been exported to countries around the world.

KwangShin is continuously conducting research and development on charging facilities to build the infrastructure for hydrogen, a major energy source of the future, and is striving to become a leading force in revitalizing the hydrogen economy and fostering clean energy, such as being selected as a hydrogen specialist company by Korea’s Ministry of Trade, Industry and Energy in 2022.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods