[INQ. NO. 2210M19] A high-speed door, manufactured by Heesung Ind., is an automatic door product that can come in handy in various industries.

This product can be quickly opened and closed in the food processing, refrigeration, shipbuilding, chemicals, military and logistics sectors, car washes, airports, and clean rooms, among others.

This product maximizes energy conservation and efficiency in line with an era of high efficiency. It is an automatic door that opens and closes at a high speed when using an air conditioner or heater in a factory.

Depending on its locations and applications, it can be installed as a dynamic roll door (automatic recovery type), a roll up door (type with general pipe), or a pack door (external large automatic door). Its curtain is flame retardant-coated PVC, making it very resistant to both low and high temperatures. It also has excellent light fastness. Thanks to these features, it can be used for a long time.

Interlinkable to Automation Lines

This product is interlinkable to an automation line. A user can open and close it with a remote control, a floor sensor, or an infrared sensor, depending on where it is placed. Air curtains and warning lights go well with it. And, depending on the application, you can include safety components.

Since it is made of a sheet, it is possible to respond quickly and minimize damage in case of an accident.

Heesung is currently distributing this product by developing markets through exports to Thailand, Indonesia, and China and is eyeing the whole Asian market.

The company has obtained a patent for an automatic door that it developed for use as a fire emergency exit.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

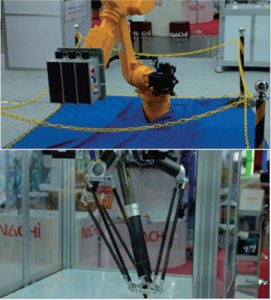

business based on its accumulated technology and product power and set a new goal of improving competitiveness through vertical integration of products. The ultimate goal of Higen Motors is to become an industry’s giant to compete against Siemens and Mitsubishi in global markets as well as domestically through the diversification of collaborative robots, starting with Delta robots and 6-axis articulated robots.

business based on its accumulated technology and product power and set a new goal of improving competitiveness through vertical integration of products. The ultimate goal of Higen Motors is to become an industry’s giant to compete against Siemens and Mitsubishi in global markets as well as domestically through the diversification of collaborative robots, starting with Delta robots and 6-axis articulated robots.