[INQ. NO. 2211M37] Frontec Co., Ltd., founded in 1978, is a 1st-tier supplier of Hyundai-Kia Motors. Frontec’s unequal cold forming technology differentiates its products from other companies’ and guarantees the best quality, longest-lasting products.

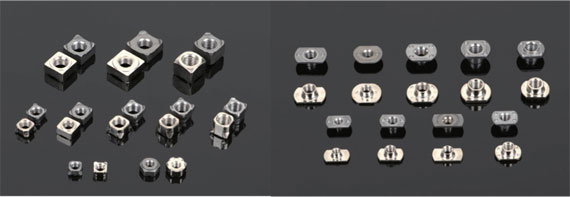

Weld Nuts

A weld nut, which is welded to the body of a car and can be combined with various structures, is a necessary part to tighten structures. It is an important strengthening part that supports various structures. A T-shaped weld nut, in particular, has higher weld strength than other weld nuts, so it is used mainly for parts requiring high strength in car bodies.

In particular, manufacturing processes of competitors inspect and pack after going through a tapping (cutting tap – chip could occur) process forging, but our company integrally composed a forging machine, a tapping (rolled tap – no chip) machine, an inspection machine, and a packing machine for the first time in Korea to manufacture products, so our products are excellent in terms of productivity, quality, and cost competitiveness compared to competitors.

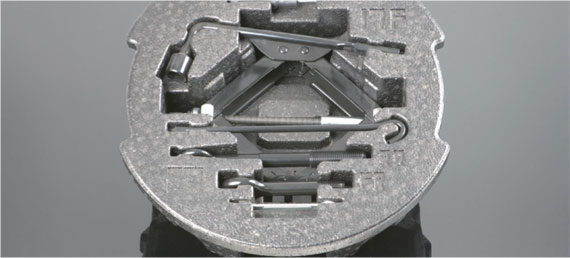

O.V.M Tool-Set, a portable tool for the replacement of a spare tire when a tire goes flat

It is a portable tool (O.V.M Tool-Set) used to put on a spare tire when you get a flat tire. It is composed of a hub wrench, a jack, and a hook that a driver needs to do a basic task in case of an emergency.

Hub Wrench

A hub wrench is used to loosen and tighten a wheel nut that secures a tire. A jack is used to lift the body of a car. It is manufactured for 700kg, 1000kg, and 1200kg depending on the allowable load and is applied to passenger cars and RVs.

Frontec is currently supplying 55% of the O.V.M Tool-Set of Hyundai-Kia Motors. It is expected that its sales will increase steadily due to the constant growth of the auto industry.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”