[INQ. NO. 2408M47] Since its establishment in 1983, YOUNG SEONG CO., LTD. has been continuously developing, based on its innovative technology and accumulated know-how, over a long period of time.

YOUNG SEONG has the largest automated manufacturing facility in Korea and mainly manufactures products such as welded wire mesh, truss girders, lattice bars, N bars, W bars, omega bars, lattice girders, stirrups, spirals, and stirrup holders that are mainly used in construction sites nationwide.

YOUNG SEONG also specializes in manufacturing various other products such as mesh fences, common steel wires, and bended wire mesh.

Through an automated production line composed of professional technicians, YOUNG SEONG strives to satisfy customers by increasing productivity and reducing production costs. Based on its technology accumulated over many years, YOUNG SEONG has obtained the Korean Industrial Standards Mark (KS) product certification and also possesses various patented technologies.

Wire mesh

Wire mesh is a grid-shaped sheet that uses cold-rolled or fresh high-strength steel wires to arrange vertical and horizontal lines at right angles and join the intersections with electric resistance welding.

The steel wires for wire mesh are classified into plain welded wire fabric and deformed welded wire fabric, depending on the steel wire used.

The plain wire fabric is attached to the concrete by a certain mechanical fixation at each wire intersection, while the deformed wire fabric is excellent for structural use ― because not only the welded intersection, but also the deformation performance of the steel wire, plays an important role in the attachment and fixation of the concrete.

The use of these products significantly shortens the work time compared to general steel rebar work. They are excellent for improving concrete adhesion performance, enhancing durability, and preventing cracks. High-quality products are made possible through a uniform production process, making it easy to maintain the precise bar arrangement and the quality.

There is a reduction in on-site work through the production process optimized for design through custom-made manufacturing. Since they are delivered as finished products that have already been welded, construction is relatively simple and even unskilled workers can work with them.

These products have specifications suitable for various types of construction sites, and have various uses. They are widely used in the construction of roads, tunnels, underground parking lots, office buildings, hotels, schools, hospitals, factories, P.C, etc.

There is a significant reduction in labor costs due to the simplification of the on-site work process.

Truss girder

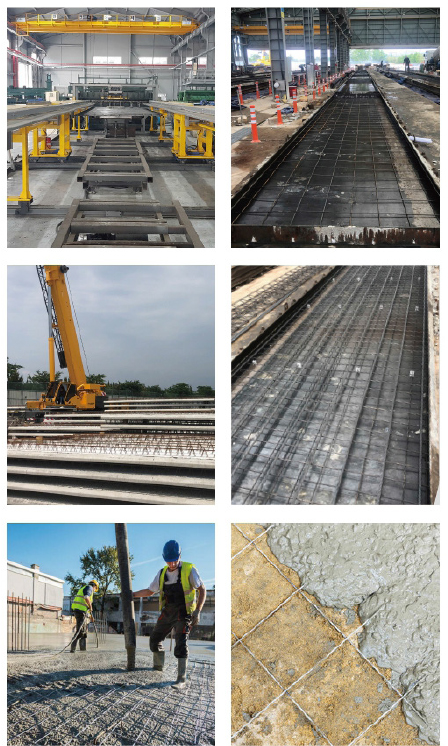

The truss girder is composed of three parts: upper reinforcement, lower reinforcement, and truss reinforcement (lattice reinforcement) that serve as a reasonable shear connection between the on-site concrete and the prefabricated (PC) plate, and the contact points of each part are integrated through electric resistance welding.

Among the construction production methods, there is the prefabricated (PC) method, and the half-slab method, which is a method that overcomes the problems that occur in the prefabricated (PC) method, and yet takes advantage of the prefabricated method. This is intended to make it easier to connect members according to partial precast, and to apply the technology as an extension of the conventional on-site steel concrete construction.

Since the half slab method also serves as a mold, the upper reinforcement of the prefabricated bar and the truss reinforcement (lattice reinforcement) are derived from the prefabricated (PC) plate, before finally the on-site concrete is formed on top of the prefabricated plate.

Lattice bar & N-bar & W-bar

Not only the shear reinforcement bars, but also the main reinforcement bars are manufactured as integral parts, which reduces a lot of work time and labor, thus making it more economical. These products are easy to arrange on-site, and they are structurally advantageous because they have good anchoring effects on the upper and lower parts.

The upper exposed surface of the shear reinforcement bar is closed, so it does not interfere with walking, which improves safety for workers.

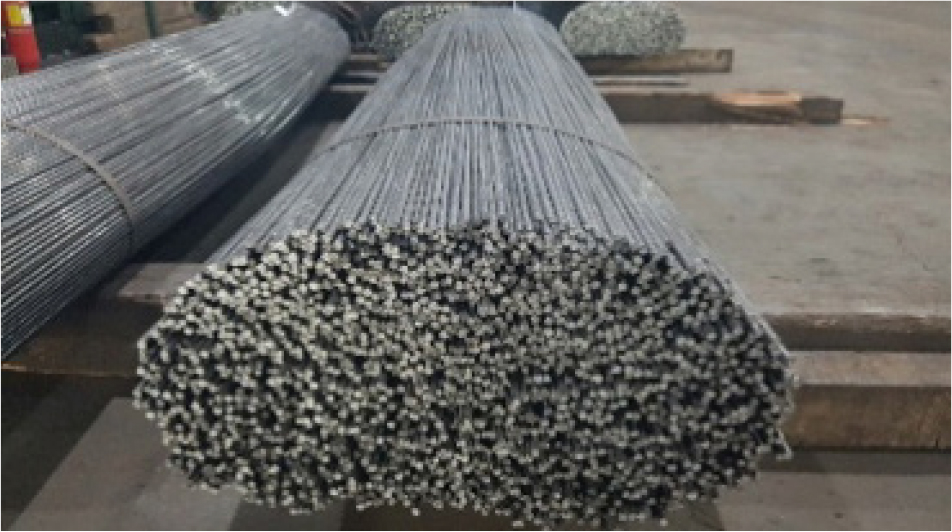

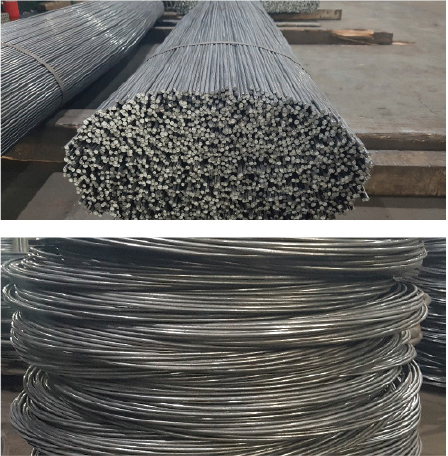

Steel wire

Ordinary steel wire is a circular wire manufactured according to KS standards by fresh processing of the raw material of mild steel wire rods, at room temperature. Its use is mainly as a reinforcing wire for wire mesh, concrete reinforcement, and hume pipes, as well as for various wire meshes and secondary products such as nails.

In particular, the deformed steel wire produced for the first time in Korea through the cold rolling process, is an ideal product for concrete reinforcement and welding wire mesh due to its high tensile strength as well as excellent adhesion of rebar.

The deformed steel wire produced by YOUNG SEONG maintains a uniform excellent joint shape through the tungsten carbide roll process, and has superior strength, adhesive force, fatigue-resistance, and elongation — compared to the indented-type wire commonly used in Korea. It can also be supplied as a straight steel wire of various specifications depending on the needs of the consumer.

Material for railroad sleepers (Bi-Block)

This product is a block-shaped sleeper that secures the rails to determine their positions, maintain the gauge accurately, support the rails on each side, and distribute the live load from the rails to the bottom of the roadbed. This material is laid in the roadbed concrete so that the block surface is exposed on the top surface.

Mesh fence

Fences are mainly used when an independent space is needed to separate the boundaries between areas or buildings such as land, schools, houses, factories, apartments, kindergartens, country houses, rest areas, parking lots, sports facilities, churches, etc., and products with appropriate functions and various designs can be manufactured and constructed according to the purpose required.

The mesh fence is typically a product made of galvanized iron wire with powder coating. The construction of the main body and mesh plate is easy, and since each is installed independently, partial repairs are simple. In addition, custom construction with various types of design fences is possible.

The company’s CEO explained, “In the current market situation where we are facing rapid changes due to the 4th industrial revolution, we are always adopting a challenging attitude by focusing on the growth of future industries in the manufacturing sector, and we are achieving increased productivity and quality improvement through smart production processes.”

He added, “We are aiming for corporate management that enables more efficient production through analysis of big data accumulated through smart factory operation. As a company that always pursues customer trust, we prioritize quality improvement and devote ourselves to customer satisfaction.”

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods