[INQ. NO. 2408M25] FLOWDY is a company specializing in the production of steam turbines, gas turbines, and turbomachinery parts. In terms of materials, it purchases and processes special alloy materials that have undergone centrifugal casting, forging, and heat treatment in the production process.

FLOWDY has been exporting its products to advanced companies related to its products in Taiwan, Panama, etc., starting with Mitsubishi in Japan in December 2018. It is currently expanding globally to Egypt, Switzerland, Nigeria, Malaysia, and Indonesia.

FLOWDY has a technique to restore damaged parts to the same level as original products with only the actual product without drawings or samples, and as a result of focusing on reverse design using 3D scanning and high-dimensional design techniques, it is receiving orders for reverse design from many countries, which is contributing to localization by reducing overseas dependence on rotating equipment.

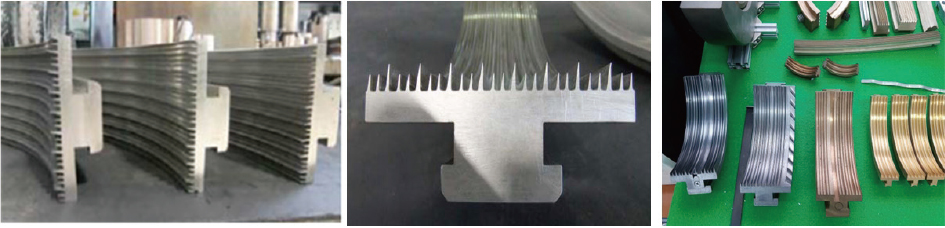

Diaphragm

Diaphragm is a modular component in which a fixed wing attached to a rotor is assembled on a ring, which adjusts the direction and speed of steam, to be effectively transmitted to the rotating wing.

Packing ring

Packing ring is a sealing device inside a turbine, installed between the stationary and rotating bodies of a turbine with high temperature and pressure to prevent steam from leaking.

Compressor blade

Compressor blade is a rotary blade installed around the circumference of a compressor disk of a gas turbine engine, which provides energy to the air when the air passes through the engine.

Impeller

Impeller is also called a runner. This is a wheel that rotates by receiving energy from steam or water with a number of blades around it in a steam turbine or reaction water turbine.

Installed in a turbocharger, 12 to 20 blades are radially installed according to a complex three-dimensional curve, and the compressor side is mainly made of aluminum, while the turbine side is made of a heat-resistant alloy. However, new materials such as ceramics are also used.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods