Tae Sung Co. was founded in 1980, and is currently a leading company in Korea in manufacturing diamond core bits. It is the only company in Korea that can provide total solutions for impregnated core bits, reamers, drill rods, core barrels, and drilling accessories.

Tae Sung has approximately 600 domestic customers and is currently exporting it top-quality products to more than 27 countries.

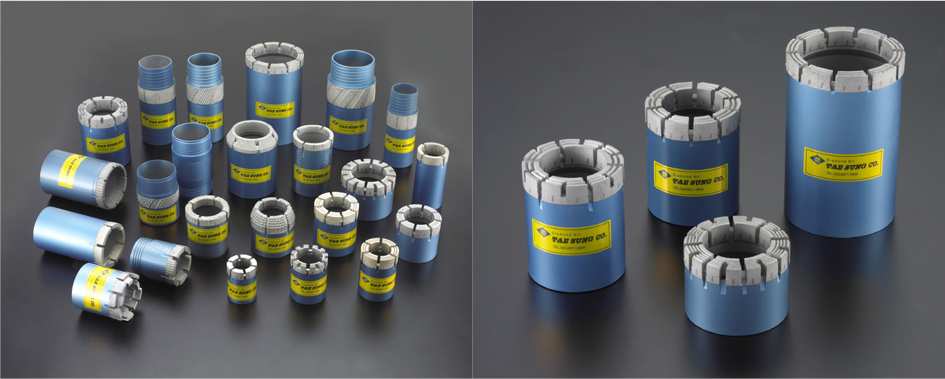

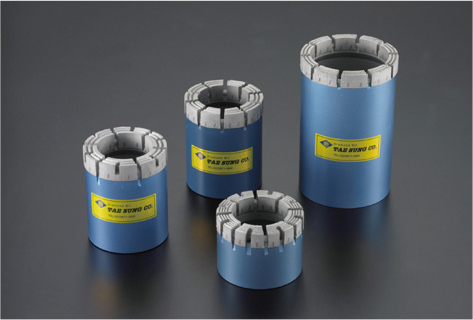

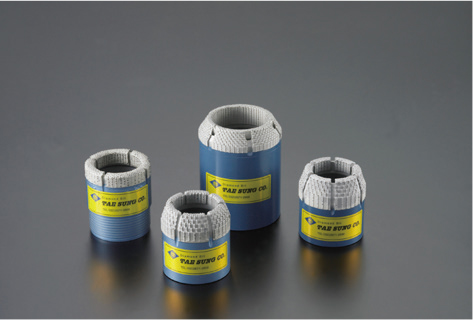

Impregnated Diamond Core Bits

Impregnated diamond core bits are attached to the foremost part of the core barrels to be used in direct drilling of the ground, and play the most important role among the equipment that is used in drilling. There are many types of bits classified and used according to the purpose of drilling or ground conditions, and the bits also differ in terms of their material, shape, and performance.

It is thus economical and highly effective in drilling works to use the proper bits after full understanding of the characteristics of each bit. Impregnated diamond core bits are used for the drilling of hard rocks, and metal bits are normally used for the ground or soft rocks.

Impregnated diamond core bits are normally used in cases where core drilling is needed, while non-core bits are used where core is not needed. However, the drilling efficiency and economic feasibility increase if core bits are used while core is not needed.

Due to the global trend of moving toward a carbon-free era, the demand for mineral resources such as for electric vehicles and batteries is expected to steadily increase in the future. Accordingly, the demand for diamond coring products produced by Tae Sung will also automatically increase, so the outlook is bright.

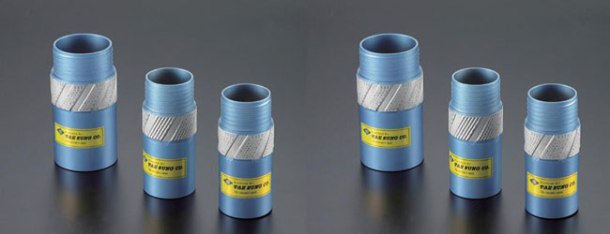

Diamond Reaming Shell (Reamer)

A diamond reaming shell is connected with a bit to be used, and the drilling by bit and grinding of side surfaces can be done simultaneously, but the drilled hole should be kept not smaller than the diameter of the bit (reaming).

It should be used to prevent early wear and tear of the outer diameter of the bit, and also to prevent vibration and deformation of the hole walls. Diamond reaming shells are produced with the outside diameter larger than that of the bit.

There are two types of diamond reaming shells — one is for general rocks, and the other is the screw-type for strong rocks.

Taesung’s diamond reaming shells have an excellent lifespan and reaming ability, as high-quality shank and natural diamond are used in producing them.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

the challenges of the Korean hard and extremely hard formations. Its impregnated diamond bits have a proven track record and they drill with better penetration rates compare to other competitive products.

the challenges of the Korean hard and extremely hard formations. Its impregnated diamond bits have a proven track record and they drill with better penetration rates compare to other competitive products. So, it is economical and highly effective in drilling works to use the proper bits after full understanding of the characteristics of each bit. Diamond core bit is used for the drilling of hard rocks, and metal bit is normally used for the ground or soft rocks. Impregnated core bit normally used in case core is needed, while noncore bit is used if core is not needed.

So, it is economical and highly effective in drilling works to use the proper bits after full understanding of the characteristics of each bit. Diamond core bit is used for the drilling of hard rocks, and metal bit is normally used for the ground or soft rocks. Impregnated core bit normally used in case core is needed, while noncore bit is used if core is not needed. Bits can be diversely produced in any sizes and specifications that are needed. Drilling speed of the impregnated core bit is very excellent compared with those of other companies. Large size diamond with the strong matrix is used for soft rocks. Medium size diamond with the matrix of medium strength is used for the rocks of medium strength. Small size diamond with soft matrix is used for strong rocks.

Bits can be diversely produced in any sizes and specifications that are needed. Drilling speed of the impregnated core bit is very excellent compared with those of other companies. Large size diamond with the strong matrix is used for soft rocks. Medium size diamond with the matrix of medium strength is used for the rocks of medium strength. Small size diamond with soft matrix is used for strong rocks. types of bits classified and used according to the purpose of drilling or ground conditions, and the bits are also different in their material, shape, and performance.

types of bits classified and used according to the purpose of drilling or ground conditions, and the bits are also different in their material, shape, and performance. is very excellent comparing with those of other companies. Large size diamond with the strong matrix is used for soft rocks. Medium size diamond with the matrix of medium strength is used for the rocks of medium strength. Small size diamond with soft matrix is used for strong rocks.

is very excellent comparing with those of other companies. Large size diamond with the strong matrix is used for soft rocks. Medium size diamond with the matrix of medium strength is used for the rocks of medium strength. Small size diamond with soft matrix is used for strong rocks.