[INQ. NO. 2209M33] GunyangITT Co., Ltd. was established in 1990 when the Korean auto industry had just advanced into the global market, and has been growing in line with the development of the Korean auto industry that presently ranks 5th in the world’s automobile manufacturers, a country that produces around 5 million vehicles per year.

GunyangITT controls more than 60% of the domestic market share in car interior machines, taking the lead in the same sector.

Starting with its first exports to Poland in 1995, GunyangITT has now advanced into 23 automotive powerhouses including Europe, the USA, Japan, and others, building up its reputation in the global market.

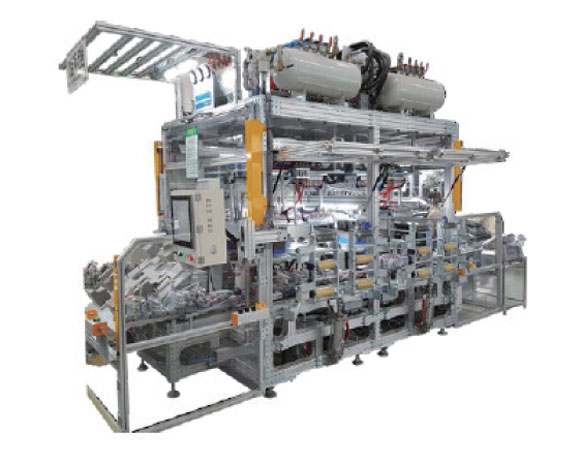

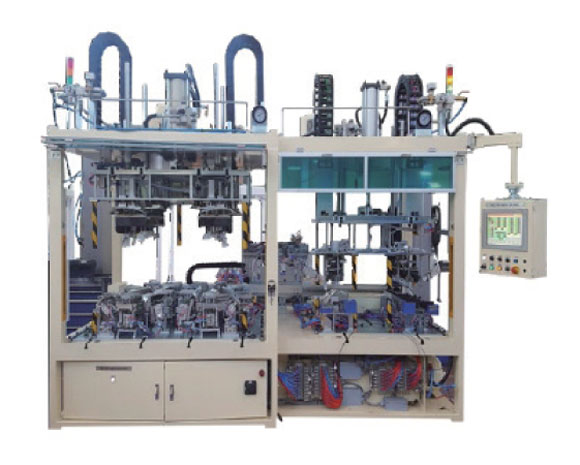

GunyangITT, as a car interior equipment manufacturer, is producing industrial machines such as IMG vacuum forming machines, laminating machines, headliner forming lines, edge folding machines, hot air stacking machines, radiant-heat stacking machines, ultrasonic stacking machines, heat-stacking machines, and others, in relation to door trims, instrument panels, headliners, truck trims, package trays and floor carpets.

Innovator in Automotive Interior Machinery

As a total solution supplier, GunyangITT can handle turnkey project and are swiftly responding to almost all kinds of support for designs, A/S services, relocations, remodeling, and other facilities.

In addition, GunyangITT can supply development tools for CAD and 3D modeling and seek high quality thanks to its cutting-edge machines. It is also working hard to realize high-quality mass-production with low costs while increasing its competitiveness.

GunyangITT makes every endeavor not only to sell excellent equipment, but also to enable customers to create better value through its equipment.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods