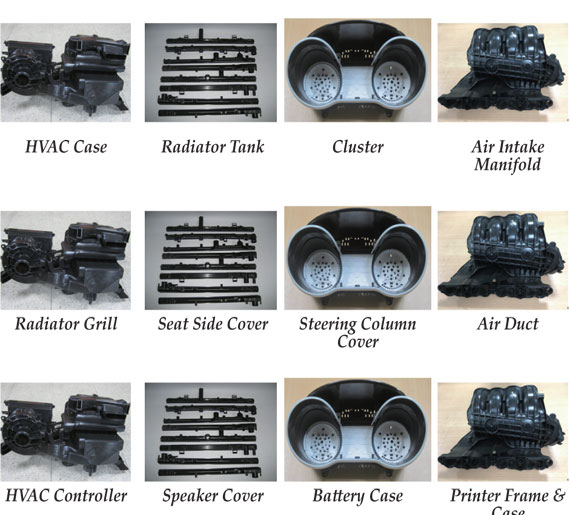

[INQ. NO. 2210M08] J.W. Engineering, Inc. (J.W.E.) was founded in 1978 as a trading company to supply rubber products used for vehicles. As J.W.E. dealt with rubber products since its establishment, it inevitably got to know all about molds and to recognize their importance.

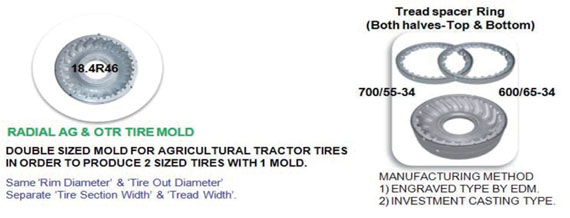

While carrying out automobile mold business since 1983, J.W.E. naturally got into making tire molds in 1986. Since then, they have become the company’s main export items.

Molds by computerized tooling processes

J.W.E.’s molds are manufactured by CNC milling and EDM on the mold body as one piece.

Thanks to these computerized tooling processes with fast coded programs and high precision, the pitches of every tire mold are uniform, correct, durable and beautiful. The company’s AG & OTR tire molds are adopted for this method only.

OTR, AG and industrial tire molds supplied by J.W.E. with over 40 years’ experience and know-how in tire mold manufacturing gives full satisfaction to customers in every aspect such as quality, delivery, technical support, and much more.

Accurate machining infrastructure, preparations for meeting customer’s specifications, and the company’s specialized quality-control procedures ensure quick delivery and trusted quality.

By establishing a joint plant in Jiangsu Province, China, J.W.E. is now providing molds for globally renowned tire factories.

The types of molds manufactured by the company are usually ‘giant-sized’ ones used for agricultural farms, mines, industrial sites, and so forth.

“We are proud that the combination of our technologies built up for some 40 years, and plant engineers working with us for more than 20 years, makes and provides high-quality molds that are well-received by any customers,” explained the CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods