Sterling Technology Inc. is an innovative company putting all its efforts into designing and developing innovative hydraulic attachments and vibratory pile drivers to meet customers’ requirements, also including customers’ applications.

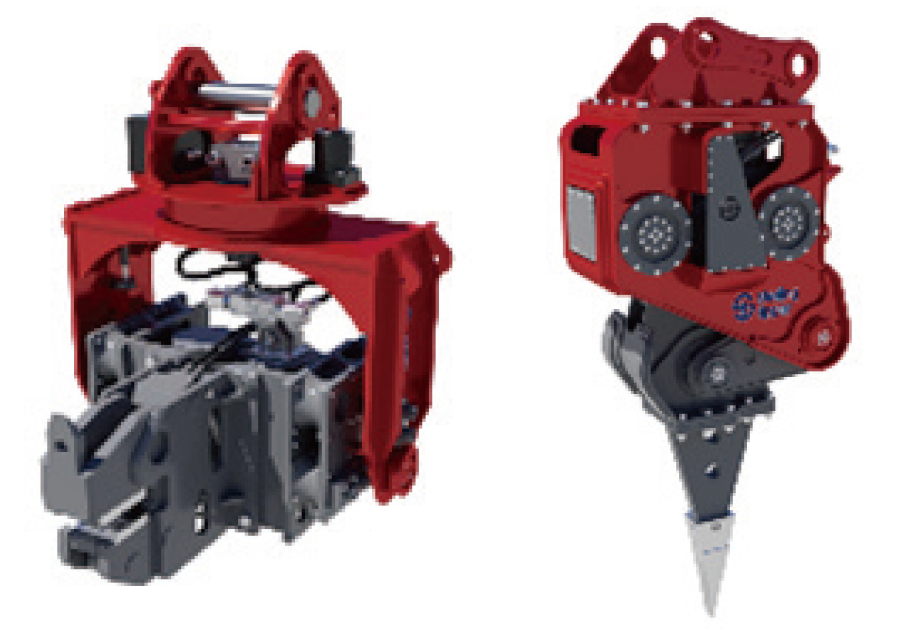

By applying this strategy, Sterling Technology ensures effective piling, quarry, and mining work with high productivity for customers. The company’s product ranges are: vibratory rippers; side grip pile drivers; and auto tilt pile hammers.

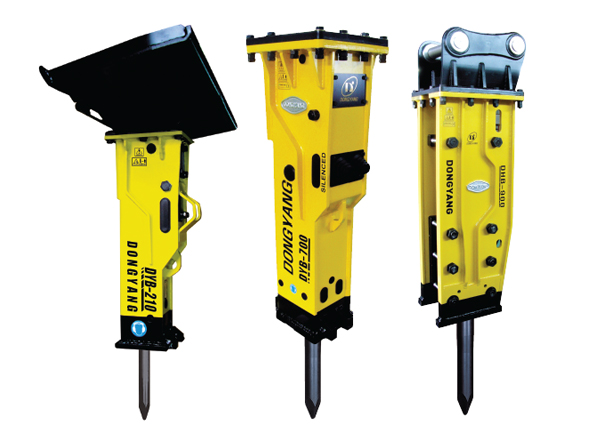

Rippers

Sterling Technology’s rippers are one of the best solutions the company supplies as an alternative or supplementary device for primary breaking of rocks for mines and construction sites ― like blasting banned areas, noise restricted areas, and underwater works.

They offer three options in tooth-type for soft & medium hard-rock; chisel-type for hard-rock; and compactor-type for compacting ground. Users can simply change it on-site any time, depending on rock types and various applications.

Maximizing productivity and minimizing down time by on-site parts replacement ensures a better class of ripper, higher productivity, rigid and higher durability at hard-rock job sites, and low maintenance cost.

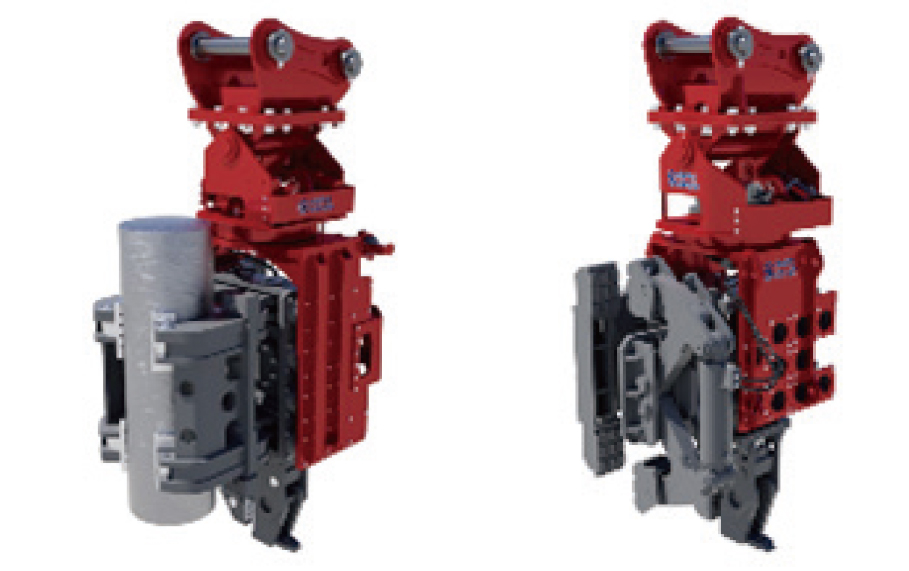

Side-Grip Pile Drivers

Sterling Technology’s side-grip pile drivers are one of the best solutions to handle, pitching, driving, and extracting piles without the need for grand crew (assistants) or assisting machinery. The use of sterling’s side-grip technology ensures higher productivity and significant cost savings. The features of the company’s side grip drivers are available for a wide range of piles (sheet piles, H beams, I-H beams, and round-piles), versatile piling at headroom-limited and confined job sites.

Precise and accurate side clamping, quicker and more powerful, low maintenance costs, easy maintenance, rigidity and durability, are ensured.

“With our hydraulic vibratory excavator attachment, you will get the best efficiency from your carrier machines. Our commitment is to offer reliable, quality products to our customers,” stressed a spokesperson for the company.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods