[INQ. NO. 2407M10] Established in 1996, DAWOON Co., Ltd. is a company that supplies various smart solutions and robotic solution products, starting with automatic feeders, for Korean cattle, plus dairy cows, poultry, and ducks.

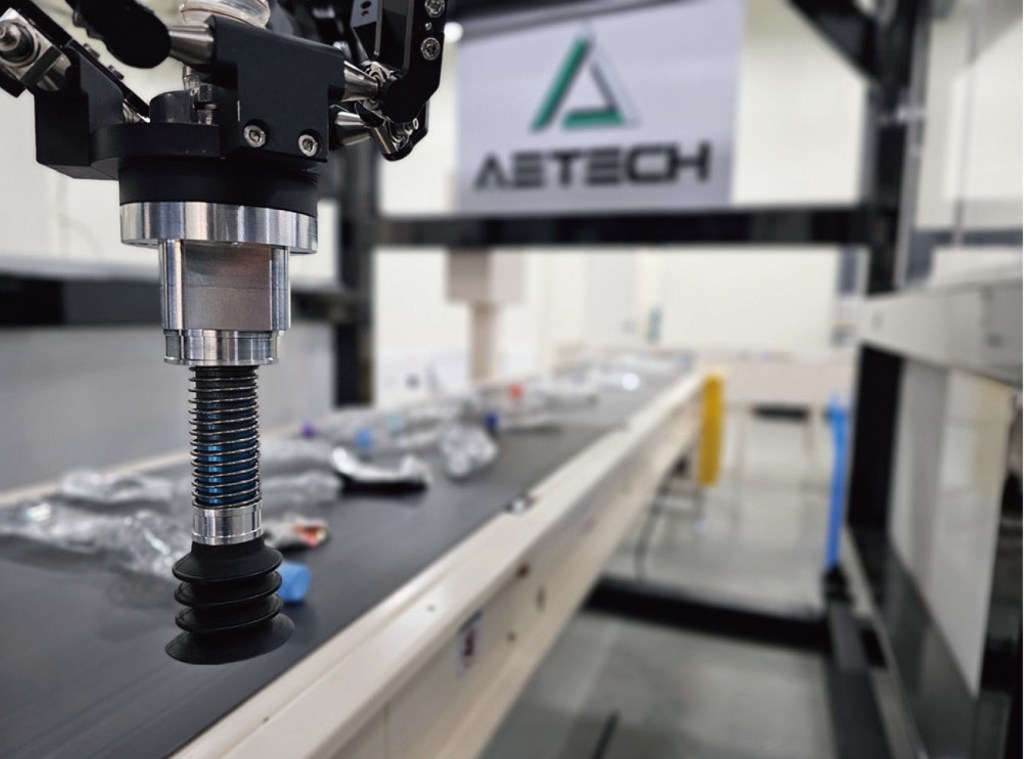

By establishing an ICT-integrated control system with advanced robot/AI technology, monitoring and remote control are provided for all types of breeding management such as livestock feeding, milking, cleaning, and barn environments — and various robots can move under the automation system in place of actual human labor.

DAWOON provides monitoring and remote control of all feeding and management such as meal feeding, milking, cleaning, livestock environments, etc. – by establishing advanced robots & AI technology, and an ICT-integrated control system.

DAWOON specializes in smart & robotic farms that provide smart unmanned livestock sheds in which various robots work through an automated system in place of actual human labor.

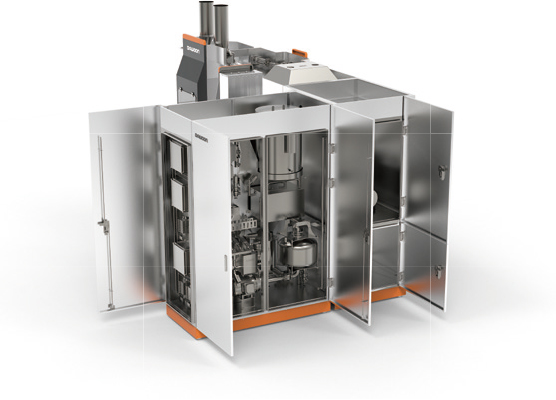

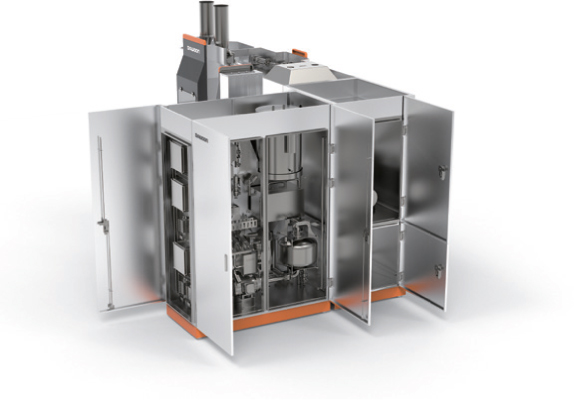

DairyBot, a robotic milking machine from DAWOON, is an unmanned milking robot that attaches a milking cup and squeezes milk after a cow enters the milking room and eats automatically supplied feed. This robot automatically performs the entire process of human washing, attaching milking cups, milking, and disinfection, all of which were originally carried out by manpower.

Realizing complete automation of milking labor

DAWOON’s robot milking machine enables the complete automation of milking labor, which takes up 67% of the working hours of dairy farms, by enabling innovative labor-reduction with robot automatic milking and automatic feeding technology.

It is an all-in-one system that integrates the cleaning, pre-milking, milking, and soaking into one process, and all processes are performed at once by attaching a milking cup. It reduces the milking time required for each process and ensures fast milking time. It implements 98% accurate nipple-recognition technology by utilizing a built-in 3D camera.

During milking, milk-quality analysis and milk-quantity measurement for each individual cow and each udder are provided to the user, and real-time confirmation and remote service of analysis results through web/mobile are available.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

have grown in more than double-digit figures. Among the developed countries, on the other hand, the USA (29.2%), the EU (34.6%), and Vietnam (87.8%), which are emerging as overseas production bases for Korean companies among rising countries, have increased their exports to ASEAN nations (48.5%) and India.

have grown in more than double-digit figures. Among the developed countries, on the other hand, the USA (29.2%), the EU (34.6%), and Vietnam (87.8%), which are emerging as overseas production bases for Korean companies among rising countries, have increased their exports to ASEAN nations (48.5%) and India.