[INQ. NO. 2309M30] Kwang Sung Steel Pipe Co., Ltd. is a precision cold drawn steel tubes manufacturer founded in 1972.

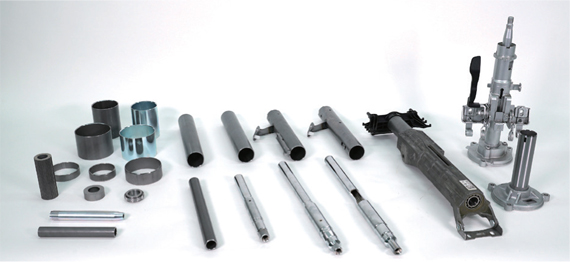

Kwang Sung Steel Pipe mainly uses electric resistance welded (ERW) and seamless pipe made of carbon steel and alloy steel as raw materials, and has the production capacity to precisely draw tube from small to large diameters.

With over 50 years of accumulated experience of solid drawing and strict quality assurance, Kwang Sung Steel Pipe has been supplying precision cold drawn steel tubes to all major industries at home and abroad, including tubes for automobile steering and suspension systems, pneumatic cylinders for heavy construction, farming equipment, and aluminum winding bobbins.

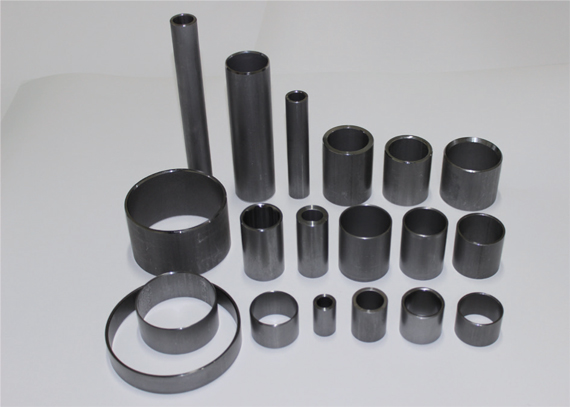

Precision cold drawn steel tubes for automotive parts, construction equipment, agricultural machinery cylinders, etc.

Kwang Sung Steel Pipe’s major products are precision cold drawn steel tubes for various automobile parts such as steering systems and suspensions; plus safty items, for hydraulic and pneumatic cylinders of heavy construction equipment; and agricultural machinery cylinders; and for aluminum winding bobbins.

Kwang Sung Steel Pipe has a wide range of production capabilities from small to large diameters (outer diameter standard Ø10~Ø267), and can implement mechanical properties that meet the needs of its customers.

In addition to precision cold drawn steel tubes, Kwang Sung Steel Pipe has its own precision cutting/chamfering facilities, so it can supply parts with cutting/chamfering according to customer requests.

“We are committed to ceaseless development of technology, investment in facility, and quality management to continuously satisfy customer expectations and to become a leading entity in the steel tube industry,” assured the company’s president.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods