[INQ. NO. 2309M28] HANSHIN TECH CO., LTD. is a total cleaning system company. HANSHIN TECH has been manufacturing washing machines for cleaning foreign substances on parts such as secondary battery cases, automobiles, and electronics for 25 years since 1998.

Two-type of cleaning methods – dipping type & spray type

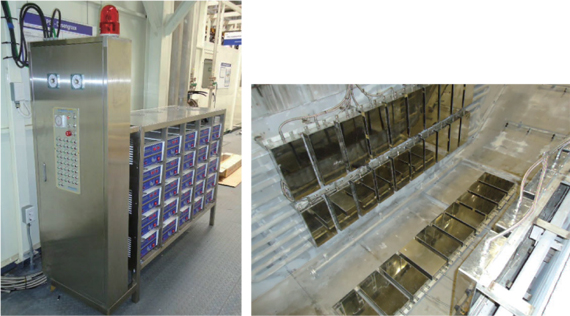

Cleaning methods are divided into dipping type and spray type, depending on the product qualities such as size, shape, weight, detergent, etc.

Dipping type is a method of washing by immersing in a tank (precipitation type) and is often used for products with a large amount of washing or many curves. Spray type is a method of placing products on a conveyor belt and washing them as they pass, and is often used for PCB boards, pallets, etc. HANSHIN TECH manufactures the customized products to increase the cleaning efficiency of parts.

Washers for automobile-related parts

HANSHIN TECH is delivering washers for automobile-related parts with many domestic auto parts companies, and in particular, it has been doing business with Hyundai Motor Company’s primary vendor company from 2002 to the present, and is exporting washers to the United States, Brazil, India, and China.

Washers for cleaning secondary battery cases

HANSHIN TECH exports washers for cleaning secondary battery cases to Poland and the United States, and it exports washers for cleaning various other parts to Russia, Mexico, Indonesia, etc.

The medium used for cleaning is water and eco-friendly detergent, which does not harm the environment. Cleaning using ultrasonic waves is currently the safest cleaning method.

“We are committed to stably supplying high-quality differentiated products through accumulated technology and continuous development. “We will strive to pioneer overseas markets and do our best to grow into a global leader,” the company’s CEO remarked.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods