[INQ. NO. 2110M14] The grease trap from Mirae Industry Co., Ltd. is a device that filters F.O.G. (fat, oil, and grease), discharged from restaurants and kitchens.

When the wastewater produced in the food treatment process passes through the grease trap, it separates the grease using the difference in density between oil and water. It prevents the oil from flowing into the sewer which can cause clogging and/or reflux in the pipe. It can also save costs of repair work and even prevent water pollution.

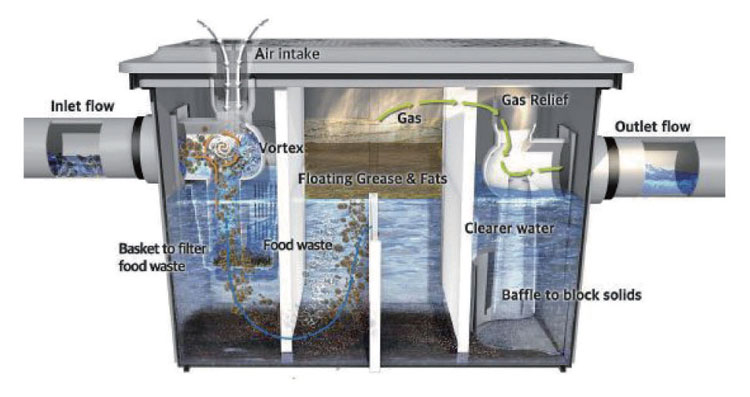

As for the operational principle, the friction between the inflow wastewater and 90° elbow connected to the inlet creates a vortex phenomenon with external air through the air-intake-hole. Wastewater flows down to the oilseparation-plate and F.O.G floats-by the plate in middle of the product, the difference in density enables grease to be separated from the water. The filtered water keeps flowing through the outlet.

Meanwhile, the odors inside the grease trap are discharged through the gas release hole in the elbow of the outlet. In regard to certification, it has obtained the CE mark with an outstanding test result. The performance of the F.O.G separation has been internationally certified, and now it is all set to advance into the global market.

Among several different models in size, the smaller ones are specifically designed for indoor use with extra features, which allow users to have no more concerns about odor issues.

First, locking levels on the edge with rubber packing on the cover allow it to be affixed strongly to the body, blocking the occurred inner gas and stench out from the product.

Also, the sight glass on the cover helps the user know when to separate the F.O.G., allowing one not to bother to open it up unless removing the grease and food waste.

These innovative ideas not only ensure substantial convenience with a pleasant experience to users, but also set these grease traps apart from others in the world.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

Leave a comment