Korean Exhibitions: Platforms for Opening the Future of Industrial Innovation

The exhibition industry is a key business platform that first introduces innovations from each country and connects companies and markets. For over 20 years, the Korean government has provided support for entities to hold exhibitions through the Domestic Exhibition Support Project for Hosting, (“the Project”) and by developing exhibitions as a strategic tool for expanding exports and enhancing national trade competitiveness.

In particular, the Project supports the holding of exhibitions to strengthen industrial growth and connections with global markets, focusing on the following three key pillars:

Fostering Exhibitions by Stage of Growth

The Project categorizes the exhibitions into three growing stages: ‘New,’‘Promising,’ and ‘Global Top,’ and systematically supports the necessary capabilities for each stage.

For the New Exhibitions, the Project provides comprehensive support for attracting small and medium-sized enterprises (SMEs), and for promotional costs to secure a stable growth foundation in the domestic market.

For the Promising Exhibitions, laying the foundation for entering the global market is important, so the Project actively supports the attraction of overseas buyers, international promotion, and hosting side events to help Korean companies to advance onto the international stage.

As international exhibitions, the Global Top exhibitions are a stage that requires the advancement of their platforms. Support is provided primarily through expanding the global networks, such as attracting overseas guests and foreign journalists.

As such, Korean exhibitions, grown through such step-by-step support, are strengthening their role as a global industry platform through innovative exhibitions that lead industry trends.

Promoting Exhibitions Centered on Strategic Industries

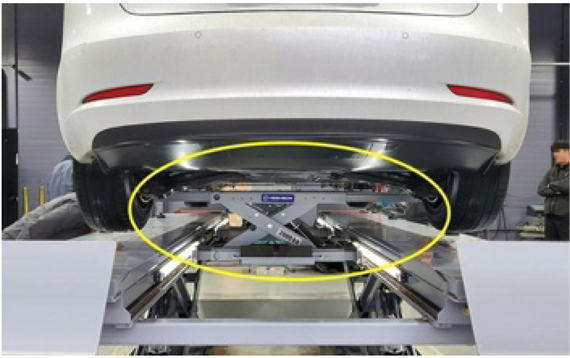

The Korean government has designated key industries — such as semiconductors, secondary batteries, biotechnology, and robotics — as strategic industries that are crucial for the national economy, and is thus encouraging exhibitions in these fields to strengthen the nation’s industrial competitiveness.

The Project comprehensively supports the development of core capabilities of strategic exhibitions that showcase new technologies and connect global partnerships across industries, leading the expansion of the industrial ecosystem.

It is expected that these strategic industry exhibitions will grow into specialized platforms for policy announcements and technology sharing, and advance to become Global Top stages for industrial innovation at prestigious international events such as the Consumer Electronics Show (CES), Hannover MESSE, and the Mobile World Congress (MWC).

Strengthening the Foundation for Fostering Regional Exhibitions

Since 2013, the government’s efforts to foster regional exhibitions have intensified as regional exhibitions have been included in the targets of the Domestic Exhibition Support Project for Hosting. Recently, support has been focused on exhibitions linked to local industries, underlining the fact that regional exhibitions serve as key venues for showcasing regional characteristics and strengths.

In this way, regional exhibitions promote local industrial growth, support local SMEs in securing business opportunities and markets, and promote relationships for mutual growth. These changes are restoring the balance of the existing exhibition industry structure, which is concentrated in the Seoul metropolitan area, and laying the foundation for strengthening regional industrial competitiveness through growing into global-level exhibitions.

Automechanika Frankfurt, a representative global brand exhibition, has expanded its exhibition franchise model to countries like China, Turkiye, Malaysia, and the UAE — establishing itself as an international business platform that aims to connect the global supply chains into a coordinated network. Similarly, some domestically organized exhibitions that have grown under the Korean government’s systematic support are actively seeking overseas market expansion and expanding their global networks.

If more exhibitions join this trend and receive continued support at the national level, domestic exhibitions are expected to grow as global brand exhibitions for each industry, securing leading positions in the global market.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods