[INQ. NO. 1605M25] Quality is the most important factor in customer‘s satisfaction. Korea Lost-Wax Co., Ltd. (KLW)’s quality assurance and acceptance procedures are fully implemented throughout each stage of the manufacturing process. KLW has approval from major aerospace engine makers with AS9100, ISO9001 and shipping registers in eight countries.

[INQ. NO. 1605M25] Quality is the most important factor in customer‘s satisfaction. Korea Lost-Wax Co., Ltd. (KLW)’s quality assurance and acceptance procedures are fully implemented throughout each stage of the manufacturing process. KLW has approval from major aerospace engine makers with AS9100, ISO9001 and shipping registers in eight countries.

KLW’s effort to increase quality level for customer’s satisfaction will ceaselessly continue.

KLW uses the latest equipment for manufacturing and supplying various kinds of casting parts to clients worldwide. Especially, KLW uses high vacuum induction furnaces for aerospace, power generation and marine industry casting parts.

KLW’s investment castings are used in many industries, particularly where high-quality series parts are required with close tolerance from materials that are difficult or even impossible to be machined. KLW’s investment castings are also used in such major areas of industries as the aerospace industry, marine industry, power generation industry, nuclear industry, and commercial industry.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

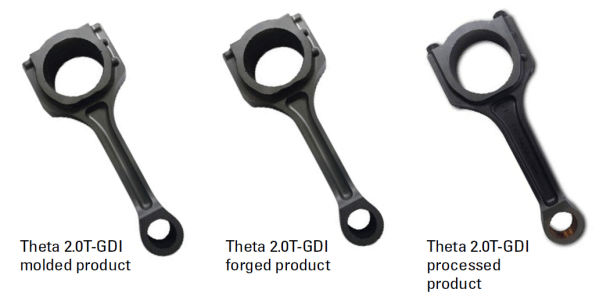

Components for automobile engines are made of aluminum, and they therefore need special molds for die casting. Coolers from Wonjin are used in the process to inject cooling water to chill the heated molds. Aluminum melts at 660°C, which means that the repeated casting process keeps the molds heated at high temperature, and may hinder separation of the components from the molds. The cooler is needed to ease the separation process by injecting water into the molds to cool them down, thus decreasing the defect rate, enhancing productivity, and prolonging the durability of the molds.

Components for automobile engines are made of aluminum, and they therefore need special molds for die casting. Coolers from Wonjin are used in the process to inject cooling water to chill the heated molds. Aluminum melts at 660°C, which means that the repeated casting process keeps the molds heated at high temperature, and may hinder separation of the components from the molds. The cooler is needed to ease the separation process by injecting water into the molds to cool them down, thus decreasing the defect rate, enhancing productivity, and prolonging the durability of the molds.