[INQ. NO. 1607M23] Since its founding in  October 1995, Taeil has dedicated itself to production and quality enhancement of hydraulic and pneumatic cylinders, and has supplied large quantities of hydraulic cylinders for major steelworks of POSCO and Hyundai Steel, etc.

October 1995, Taeil has dedicated itself to production and quality enhancement of hydraulic and pneumatic cylinders, and has supplied large quantities of hydraulic cylinders for major steelworks of POSCO and Hyundai Steel, etc.

Taeil’s hydraulic and pneumatic cylinders were designed and produced to suit the conditions of different operating environments, thus extending the general lifecycle of the products. They are cheaper in unit price than other products, thanks to more than 20 years of manufacturing experience.

They are exported to Japan without any tests by contractors, for even the fastidious Japanese buyers trust Taeil’s original tests completely. Taeil aims always to produce and supply the most optimized products to meet the best interests and satisfaction of customers. Taeil promises it will further work hard to maintain its lead in the industry by managing its global operations with a long-term perspective and enhancing the welfare of all its members.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

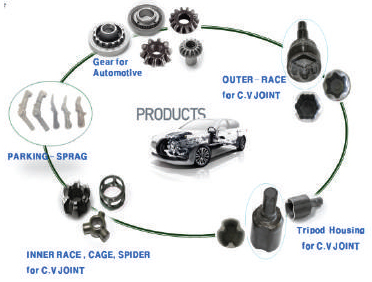

Taechang Forging mainly produces tripod housing of automobile steering mechanism parts, as well as gears and packings of gearbox parts. Taechang Forging equally specializes in cold forging, filming, and lubrication, and produce radiation parts. Taechang Forging mainly produces c-v joint along with tripod housing & spider and outer race & inner race and cage as detailed parts. Tripod housing conveys driving power from transmission to spider, and again, to outer race through drive-shaft. The outer race conveys the driving force from the drive-shaft to the inner race, and again, to outer race to tires.

Taechang Forging mainly produces tripod housing of automobile steering mechanism parts, as well as gears and packings of gearbox parts. Taechang Forging equally specializes in cold forging, filming, and lubrication, and produce radiation parts. Taechang Forging mainly produces c-v joint along with tripod housing & spider and outer race & inner race and cage as detailed parts. Tripod housing conveys driving power from transmission to spider, and again, to outer race through drive-shaft. The outer race conveys the driving force from the drive-shaft to the inner race, and again, to outer race to tires.

The most notable products of TCT are: components for turbo compressor wheels(impellers, blades, blisks, diffusers and inducers), which are applied to gas turbine engines and turbo machineries (includingcompressors, pumps, blowers and chillers), rockets for spacecraft, thrusters for guided weapons, and other defense andcommercial equipment. TCT also produces components for airplane bodies, as well as naval propellers, for military andcommercial aircraft, and for shipbuilding & marine organizations.

The most notable products of TCT are: components for turbo compressor wheels(impellers, blades, blisks, diffusers and inducers), which are applied to gas turbine engines and turbo machineries (includingcompressors, pumps, blowers and chillers), rockets for spacecraft, thrusters for guided weapons, and other defense andcommercial equipment. TCT also produces components for airplane bodies, as well as naval propellers, for military andcommercial aircraft, and for shipbuilding & marine organizations.

The incinerators perform very well for wastes with high heat value, such as PE, PP, tires, rubber, leather, urethane and Styrofoam, and have adopted an unmanned automatic system without any need for operators or methods to input continuously by manpower. Instead, they have adopted air control incinerating methods that induce complete combustion with fine control of infl ow rate of combustion air by special electric pin air nozzle With a freeze protection system installed, the disadvantages of the water cooling system have been supplemented completely. A separate heating facility is unnecessary as water supply and shower facilities can be used by factories, and for offi ce heating and clean hot water.

The incinerators perform very well for wastes with high heat value, such as PE, PP, tires, rubber, leather, urethane and Styrofoam, and have adopted an unmanned automatic system without any need for operators or methods to input continuously by manpower. Instead, they have adopted air control incinerating methods that induce complete combustion with fine control of infl ow rate of combustion air by special electric pin air nozzle With a freeze protection system installed, the disadvantages of the water cooling system have been supplemented completely. A separate heating facility is unnecessary as water supply and shower facilities can be used by factories, and for offi ce heating and clean hot water.

For export of its highest-quality ultra-precision items, IPEC is manufacturing its products conforming to the manufacturing levels on par with international standards, in cooperation with the country’s well-known global level related institutes.

For export of its highest-quality ultra-precision items, IPEC is manufacturing its products conforming to the manufacturing levels on par with international standards, in cooperation with the country’s well-known global level related institutes.