FLOWDY is a manufacturing company specializing in rotating turbine parts for steam turbines and gas turbines. The company directly handles all processes, including the processing of special alloy materials through centrifugal casting, forging, and heat treatment, to ensure high-quality production.

Starting with Japan, FLOWDY began exporting to major global companies in Taiwan, Panama, and other advanced markets. The company has since expanded its presence to global markets, including Egypt, Switzerland, Nigeria, Malaysia, Indonesia, and more.

Additionally, FLOWDY has developed a unique technique to restore damaged parts to their original specifications using only the actual product, without requiring drawings or samples.

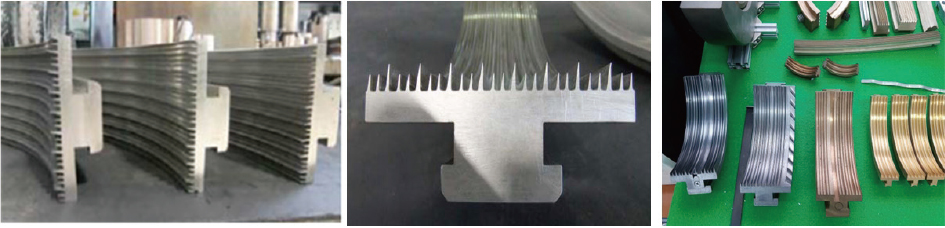

Diaphragm

The diaphragm is one of the key components of a compressor, positioned between the rotating rotor and the stationary parts to regulate pressure and airflow within the compressor. This component works in conjunction with the rotating rotor to optimize the compression and flow of air, and collaborates with the stationary vanes (stator) to maintain an efficient compression system.

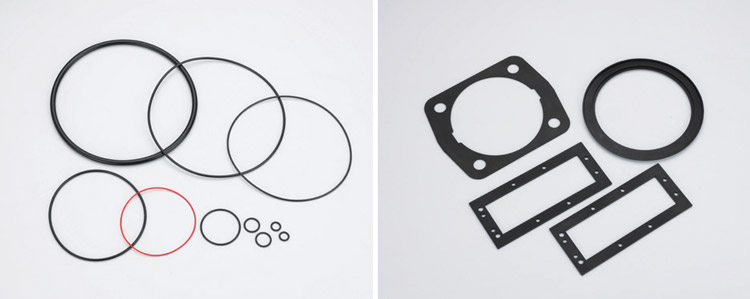

Packing Ring

The packing ring is a sealing device used inside a turbine to prevent the leakage of steam or gas. It is typically installed between the stationary and rotating parts of the turbine, where high temperatures and pressures are present. It serves as a barrier to seal the gap between these parts, ensuring that steam or gas does not escape.

Impeller

The impeller, also known as a runner, is a component used in rotating machines such as steam turbines and reaction turbines. It is equipped with multiple blades that receive energy from steam or water and rotate, playing an important role in transferring energy.

The impeller installed in a turbocharger typically has 12 to 20 blades arranged radially. The compressor side is usually made of aluminum, while the turbine side is made of heat-resistant alloys. Recently, new materials such as ceramics are also being used.

By focusing on reverse design using 3D scanning and advanced design techniques, FLOWDY is receiving numerous orders from various countries for its reverse-design projects. This innovation contributes significantly to localizing the production of rotating equipment, thus reducing dependence on overseas suppliers.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods