[INQ. NO. 2306E05] Daesung Hi-tech Co., Ltd., established in 1995, started its first business with Yamazaki Mazak by supplying high-precision parts in 1997. It has been highly acknowledged as one of the companies having top class technical skills in the Japanese market over the past 26 years.

Daesung Hi-tech exports such high-quality parts to a variety of countries such as Japan, the UK, Singapore, etc. As much as 85% of its profits are being made from exporting goods. Moreover, Daesung Hi-tech acquired AS9001 (Aerospace quality certificate), which makes it competitive in the aerospace market.

Its main products are high-precision parts, units, jig fixes, high-precision ass’y, automatic lathes, hobbing machines, and tapping centers.

Index Coupling (Hirth Type)

This is the device used for delivering the rotation from one shaft to another. It is different from the clutch, and it is impossible to cut the delivery of power randomly during the rotation as it connects the two shafts directly.

It is classified into the fixed type that connects the two shafts semi-permanently, the movable type that somewhat allows movement between the two shafts, and the retractable type that is used when the two shafts form a certain angle.

Daesung Hi-tech’s coupling, being self-developed, is exported all over the world including Japan. This product is used for splitting positions of such equipment as the index table, NC lathe, turret device, etc., and is convenient for semi-finishing due to excellent durability and high-power delivery.

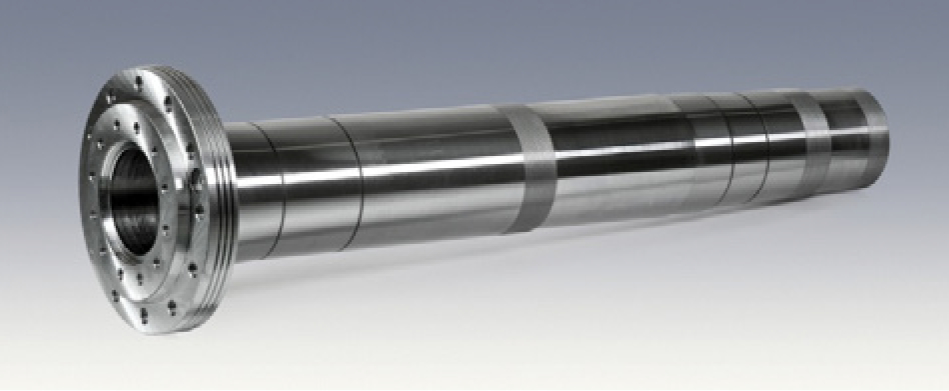

Spindle Spacer

Spindle spacer is a spacer for fixing the spindle bearing which is the core of the machine tool, and it is a high precision product requiring up to 0.001 parallelism; applicable to various kinds of spindle bearings.

Collet

Collet is a part for fixing a drill or an end mill, and there are multiple grooves on the cylinder-shaped barrel of the collet.

By tightening the barrel with uniform force from the outside using the screw, the collect is tightly fixed to the drill or the end mill which is inserted into the barrel.

Daesung Hi-tech’s collet is a unit part for fixing the M/C seal that is a functional product which is complex in the process of each part and requires high precision.

Daesung Hi-tech is emphasizing its capability and influence – not only in the field of machine tools but also in the field of other industrial machines – in order to make much more profit, as well as to take a huge step forward in the various industrial markets.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

materials and at various angles, and is one of the key components. Through module engineering, the company got the chance to make jigs for schools and research centers engaged in developing new technologies domestically.

materials and at various angles, and is one of the key components. Through module engineering, the company got the chance to make jigs for schools and research centers engaged in developing new technologies domestically. separating envelope to separate the electrode in the battery into a cathode plate and an anion plate. This product is a localized form of a UK product produced for Delco Co., Ltd. In the process of this product, precision machining, heat treatment, and surface treatment are applied.

separating envelope to separate the electrode in the battery into a cathode plate and an anion plate. This product is a localized form of a UK product produced for Delco Co., Ltd. In the process of this product, precision machining, heat treatment, and surface treatment are applied. JUNGSU TECH develops new process technologies with commitment and passion, and it will use all its capabilities to develop the products and technologies that clients need through fast data collection and changing its approach where needed.

JUNGSU TECH develops new process technologies with commitment and passion, and it will use all its capabilities to develop the products and technologies that clients need through fast data collection and changing its approach where needed.

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”