[INQ. NO. 2106M01] Dongil Canvas Engineering Co., Ltd. has ever since its establishment in 1991 been continuously developing and upgrading belt presses, filter presses, centrifugal dehydrators, screw dehydrators, and multi-circle dehydrators – in order to recommend what it called optimal dehydrators depending on the kinds of sludge – through intensive investment in technology development.

Backed by such efforts, Dongil Canvas Engineering acquired several performance certifications and more than 110 patents, thereby growing into a leading enterprise in the domestic sludge treatment area.

Recently, with government funding support, Dongil Canvas Engineering came to directly manufacture price-competitive filter presses for filter plate moving type.

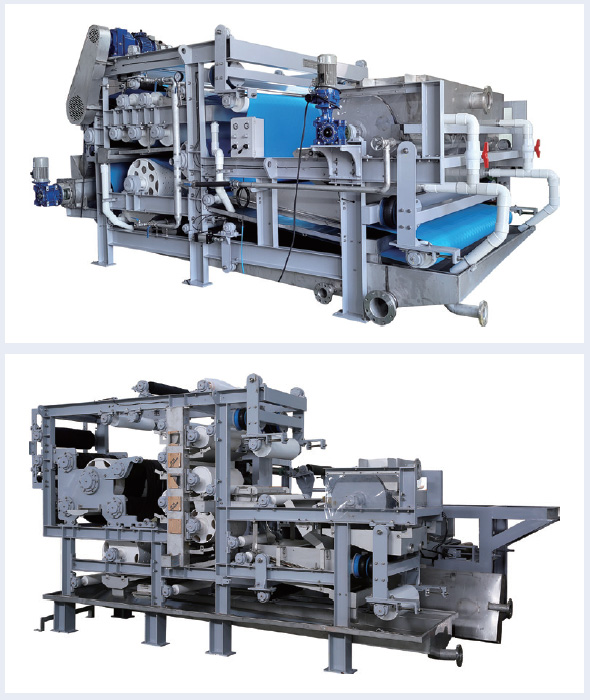

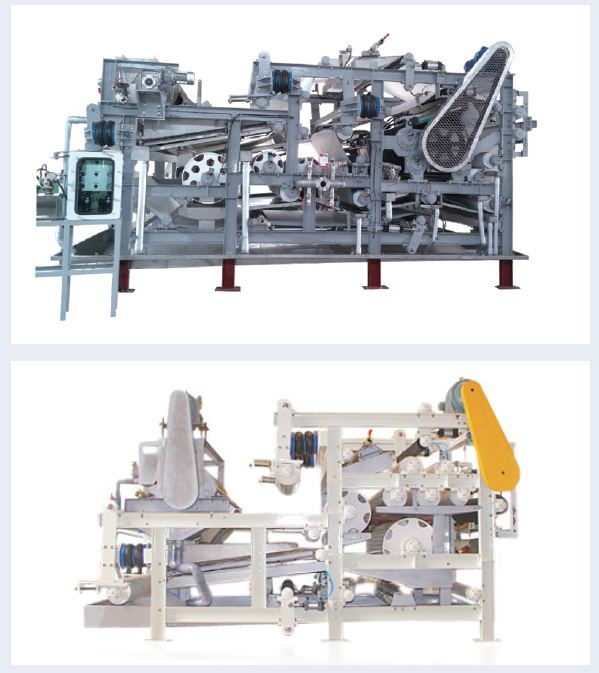

Belt press is able to filter by adding pressure on the filter plate moving type through a roller after supplying processing materials in between two sheets of filter plate moving type. A low function rate of cake is ejected by applied high-pressure in the high-pressure dehydration part – after filtering and dehydrating in advance in both the gravity dehydration part and the low-pressure dehydration part.

Belt press is available for the treatment of dehydrating sludges of various kinds of waste waters such as sewage and excreta. Dongil Canvas Engineering designs and manufactures four types of belt presses – from general belt press to vertical pressurized belt press – in order to accomplish the cake function rate that meets each customer’s needs. Moreover, Dongil Canvas Engineering produces by itself filter plate moving type that play a critical role in separating water in water-containing sludges.

Established in 1999, Dongil Canvas Engineering was consecutively designated as an excellent eco-friendly domestic enterprise in 2020. In May of the same year, Dongil Canvas Engineering was selected as a specialized company of materials, parts, and equipment. And in June, Dongil Canvas Engineering was chosen as a global small giant company, which means that it finally acquired global competitiveness in tough global markets.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods