[INQ. NO. 2011M39] Since its establishment in 1986, SHINYOUNG Co., Ltd. has continued to invest in R&D and technical development to become the best small construction equipment manufacturer in Korea.

The company has gained the trust of many customers at home and abroad – based on high-quality products and price competitiveness that meet customer satisfaction.

SHINYOUNG’s SYV series of concrete vibrator action units provide the utmost performance and power. With RPM of 3,000, the rotating parts get less worn out while helping to remove concrete bubbles to make the surface smooth and soft. It is possible to customize rubber hose length for each of the various diameters.

The rebar bender from the company is portable and designed to be continuously used through precise curves. Equipped with a latching device that is able to set two angles in advance, the rebar bender with powerful performance can save valuable working hours. Thanks to its efficient performance, one is able to very simply and safely conduct relevant jobs.

SHINYOUNG’s handy rebar cutter enables one to safely and efficiently cut rebar. The cutter is the lightest in weight, creates a precisely-balanced effect, and provides the most stable performance thanks to the superlatively forged body.

SHINYOUNG is also manufacturing a user-friendly compressor by using an aluminum pulley and rotor.

SHINYOUNG is producing a number of products on its own. And the company has acquired the quality certification mark of CE and is exporting its products manufactured in Korea to many countries around the world. The company is working hard to provide high-quality products to readily meet customers’ particular requests.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

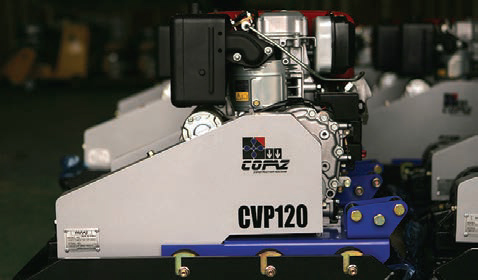

Based on its long-accumulated technologies, the company has acquired international certifi cations such as ISO 9001 and 14001, CE and GOST. Its products are being shipped to some 30 countries mainly in North America, the Middle East, Europe and North Africa, under the fi rm’s own brand “COPAZ.” Placing top priority on quality and durability, the maker has developed some 90% of its machinery’s parts with its own technology. Some key parts are supplied from advanced companies in Germany, Italy and Japan. As a result, the fi rm’s products have gained high reputations in both domestic and international markets.

Based on its long-accumulated technologies, the company has acquired international certifi cations such as ISO 9001 and 14001, CE and GOST. Its products are being shipped to some 30 countries mainly in North America, the Middle East, Europe and North Africa, under the fi rm’s own brand “COPAZ.” Placing top priority on quality and durability, the maker has developed some 90% of its machinery’s parts with its own technology. Some key parts are supplied from advanced companies in Germany, Italy and Japan. As a result, the fi rm’s products have gained high reputations in both domestic and international markets.

Placing top priority on quality and durability, the maker has developed some 90% of its machinery’s parts with its own technology. Some key parts are supplied from advanced companies in Germany, Italy and Japan. As a result, the fi rm’s products have gained high reputations in both domestic and international markets.

Placing top priority on quality and durability, the maker has developed some 90% of its machinery’s parts with its own technology. Some key parts are supplied from advanced companies in Germany, Italy and Japan. As a result, the fi rm’s products have gained high reputations in both domestic and international markets. Most of the maker’s small construction machines are being exported with a one-year warranty, and even a two-year warranty is provided for some items. Since the fi rm produces and possesses most of the machine parts, it can deliver the required parts within one or two days, resulting in swift after-sales activities.

Most of the maker’s small construction machines are being exported with a one-year warranty, and even a two-year warranty is provided for some items. Since the fi rm produces and possesses most of the machine parts, it can deliver the required parts within one or two days, resulting in swift after-sales activities.